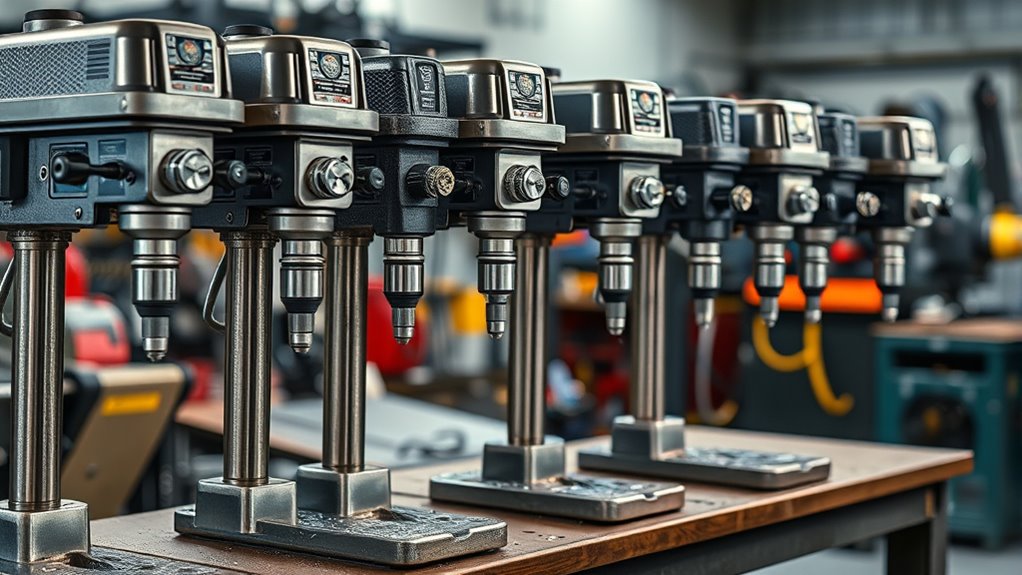

If you’re looking for the best drill presses for metalworking in 2026, I recommend models with powerful motors, variable speeds, and sturdy cast iron bases for stability and precision. Brands like WEN, JET, and Klutch offer reliable options with safety features like guards and laser alignment tools. Consider their size, capacity, and safety enhancements to match your project needs. Keep exploring further to find the perfect fit for your metalworking tasks.

Key Takeaways

- Look for models with 6.2-amp motors and variable speeds up to 3300 RPM for versatile metalworking.

- Prioritize heavy-duty cast iron bases and durable construction for stability and long-term performance.

- Choose drill presses with digital readouts and laser alignment tools for enhanced precision.

- Ensure safety features like lexan shields and easy-to-install safety guards for user protection.

- Consider size and weight for workspace compatibility, balancing power capacity with portability.

WEN 10-Inch Benchtop Drill Press with Laser

If you’re looking for a reliable and precise drill press for metalworking projects, the WEN 10-Inch Benchtop Drill Press with Laser is an excellent choice. Its 6.2-amp induction motor delivers enough power for a variety of tasks, while the compact size and 57-pound weight guarantee stability and portability. The drill offers a 10-inch swing, 2-inch spindle travel, and an adjustable work table to handle different projects. With variable speeds from 530 to 3100 RPM, a digital readout, and a built-in laser for accurate alignment, it’s perfect for detailed metalwork. Plus, it includes a keyed chuck, depth stop, and beveled capabilities.

Best For: DIY enthusiasts, hobbyists, or professionals needing a precise, reliable drill press for metalworking projects with accurate alignment features.

Pros:

- Powerful 6.2-amp motor handles various drilling tasks with ease.

- Variable speed control from 530 to 3100 RPM with digital readout for precise adjustments.

- Built-in laser for accurate alignment, ensuring precision in detailed projects.

Cons:

- Weighs 57 pounds, which may impact portability for some users.

- Limited to benchtop use, not suitable for heavy-duty industrial applications.

- The size (13.2 x 19.3 x 33.9 inches) may require dedicated workspace.

ATS Safety Drill Press Guard (Econ-Series)

The ATS Safety Drill Press Guard (Econ-Series) stands out as an excellent safety upgrade for small to mid-size drill presses, especially those used in workshop environments where quick adjustments are essential. It fits column diameters from 2.0 to 4.0 inches and throat distances of 5-10 inches, making it versatile for various setups. The guard installs easily in under five minutes with a T-Slotted aluminum clamp, no drilling needed. Its 1/4-inch thick lexan shield provides durable protection, and the flip-up design allows quick access for tool changes. Finished in high-visibility OSHA safety orange, it ensures safety without sacrificing workflow.

Best For: DIY enthusiasts and workshop professionals seeking a quick, reliable safety upgrade for small to mid-size drill presses.

Pros:

- Easy installation in under 5 minutes without drilling required.

- Made from durable 1/4-inch thick lexan for robust protection.

- Flip-up shield design allows quick access for tool and part changes.

Cons:

- Compatible only with drill presses that have column diameters of 2.0 to 4.0 inches.

- May require adjustments for non-standard throat distances outside 5-10 inches.

- Limited to small and mid-size drill press models, not suitable for larger industrial presses.

WEN 12-Inch Drill Press with Variable Speed

Looking for a drill press that offers precise control and versatile features for metalworking projects? The WEN 12-Inch Drill Press with Variable Speed fits the bill perfectly. Its 6.2-amp motor and adjustable speed range from 580 to 3100 RPM give me the flexibility to tackle various materials with accuracy. The digital readout ensures I set the exact RPM needed, while the cast iron construction provides stability during heavy-duty tasks. With a spacious work table, laser alignment, and onboard chuck storage, this drill press combines power, precision, and convenience—making it a reliable choice for any serious metalworker.

Best For: metalworkers and DIY enthusiasts seeking precise control and versatile drilling features for detailed projects.

Pros:

- Variable speed adjustment from 580 to 3100 RPM allows for flexible material handling

- Digital RPM readout ensures accurate speed setting for precision work

- Durable cast iron construction provides stability during heavy-duty tasks

Cons:

- Weighs 85 pounds, which may be cumbersome for portable use

- Limited work surface size may restrict larger projects

- Higher price point compared to basic drill presses with fewer features

JET 12-Inch Benchtop Drill Press

For those seeking precision and stability in a compact package, the JET 12-Inch Benchtop Drill Press (Model JWDP-12) stands out as an ideal choice. It features a powerful 1/2 HP motor with variable speeds from 530 to 3,100 RPM, giving me precise control for various drilling tasks. Its sturdy 10 x 16-1/8 cast iron base fits well on small workbenches, ensuring stability. The oversized ergonomic knobs make adjustments easy, while the LED work light improves visibility. I appreciate the retractable roller extension for support and the linear scale with a depth stop for consistent results. The XACTA Laser system guarantees accurate drilling every time.

Best For: DIY enthusiasts and small workshop users seeking precise, stable drilling with limited space.

Pros:

- Variable speed from 530 to 3,100 RPM for versatile drilling tasks

- Compact 10 x 16-1/8 cast iron base fits on small workbenches

- Features an XACTA Laser system for enhanced drilling accuracy

Cons:

- May be less powerful for heavy-duty industrial applications

- Limited to 12-inch capacity, not suitable for larger workpieces

- Requires electrical power at 115V, which may not be compatible everywhere

Klutch 13in. Benchtop Drill Press, 3/4 HP

If you need a reliable benchtop drill press capable of handling metalworking tasks, the Klutch 13-inch model with a 3/4 HP motor is an excellent choice. It offers variable speeds from 220 to 3,300 RPM across 16 settings, allowing precise control for different materials. The 5/8-inch chuck and 1-inch drilling capacity handle a variety of projects, while the 3-3/8 inch stroke ensures consistent depth. Its quick-release worktable tilts 45° and rotates 360°, providing versatility. The sturdy 13-inch design, combined with comfortable adjustments, makes this drill press a solid, powerful tool for metalworking enthusiasts.

Best For: DIY enthusiasts and metalworking hobbyists seeking a versatile, powerful benchtop drill press for precision drilling on various materials.

Pros:

- Variable speeds from 220 to 3,300 RPM allow precise control for different projects.

- 13-inch benchtop design with 360° rotatable and 45° tilting worktable enhances versatility.

- Robust 3/4 HP motor provides ample power for drilling metal, wood, and plastic.

Cons:

- The 1-inch drilling capacity may be limiting for larger projects.

- Weight and size could require a sturdy workspace for stable operation.

- Limited to benchtop use, lacking portability for mobile jobs.

VEVOR 8″ Benchtop Drill Press with Adjustable Speed

The VEVOR 8″ Benchtop Drill Press with Adjustable Speed stands out for those seeking precise, versatile drilling in a compact design. Its 3.2A induction motor delivers strong power and stability, perfect for extended use. With five adjustable speeds from 750 to 3200 RPM, switching is quick and easy via belt adjustment, making it adaptable to various materials. The drill supports up to 1/2 inch diameter holes and features an adjustable depth stop plus 2-inch spindle travel for accuracy. Its thick metal worktable tilts up to 45°, and an integrated LED light ensures clear visibility. This makes it a reliable choice for detailed metalworking projects.

Best For: hobbyists, DIY enthusiasts, and small workshop users seeking precise, versatile drilling capabilities in a compact benchtop design.

Pros:

- Powerful 3.2A motor ensures stable and extended use.

- Adjustable speed range (750-3200 RPM) allows for versatile material drilling.

- Tilting worktable up to 45° provides flexibility for complex projects.

Cons:

- Limited drilling capacity of 1/2 inch may not suit larger projects.

- Belt adjustment for speed changes may require manual effort.

- Compact size might restrict use for heavy-duty industrial applications.

WEN 10-Inch Benchtop Drill Press with LED Light

The WEN 10-Inch Benchtop Drill Press with LED Light stands out for anyone seeking a durable and stable machine for precise metalworking. Its cast iron construction provides excellent stability during operation, ensuring accurate drilling. The 6.2-Amp motor delivers five adjustable speeds, from 630 to 3300 RPM, allowing me to work with various materials easily. The 10-inch swing and 2-inch spindle travel accommodate a wide range of projects. An LED work light improves visibility, while the adjustable worktable and depth stop enhance precision. With a two-year warranty and essential accessories included, this drill press offers reliable performance and versatility for both hobbyists and professionals.

Best For: Hobbyists and professionals seeking a durable, precise drill press with versatile speed options for woodworking, plastic, and metal projects.

Pros:

- Cast iron construction offers excellent stability and durability during operation

- Five adjustable speeds (630 to 3300 RPM) accommodate various materials and projects

- Features like LED work light and adjustable worktable enhance visibility and precision

Cons:

- Slightly larger footprint may require sufficient workspace setup

- Belt adjustment for speed changes can be time-consuming for frequent adjustments

- The base size (8.2 x 13.5 inches) may limit mobility and portability

Factors to Consider When Choosing a Drill Press for Metalworking

When selecting a drill press for metalworking, I focus on key factors like power and motor strength to handle tough materials. I also consider the drilling capacity and size to make certain it fits my projects, along with adjustable speed controls for versatility. Safety features and precision tools are essential to keep operations safe and accurate.

Power and Motor Strength

Choosing the right drill press for metalworking hinges considerably on its power and motor strength. A robust motor, typically between 0.75 HP and 1.5 HP, is essential for efficiently drilling through thick or hard metals. Higher amperage motors deliver increased torque, ensuring consistent performance with dense materials. The motor’s design, whether induction or universal, influences durability and smooth operation during continuous use. Adequate power allows the drill press to handle larger drill bits and deeper cuts without stalling or overheating, which is critical for heavy-duty tasks. Selecting a machine with sufficient motor strength reduces strain on the tool and minimizes wear and tear over time. Overall, effective power and motor performance are key to achieving precision and efficiency in metalworking projects.

Drilling Capacity and Size

Selecting the right drill press requires careful consideration of its drilling capacity and size to match your project needs. The drilling capacity tells you the maximum diameter of holes the machine can handle—crucial for larger metalworking tasks. Size factors like swing and throat depth determine the size of workpieces you can comfortably work with. A bigger swing allows you to drill larger diameters, while more throat depth helps accommodate thicker materials. Additionally, spindle travel affects how deep you can drill without repositioning the workpiece. It’s important to choose a drill press that can handle the thickness and dimensions of your metals. In conclusion, consider the overall footprint to ensure the machine fits comfortably within your workspace while meeting your size requirements.

Speed Range and Control

Have you ever struggled to find the right speed for drilling different metals? A wider speed range makes it easier to handle various materials and thicknesses, giving you more versatility. Precise control, often through variable speed dials or digital readouts, helps you set the exact RPM needed for each job, improving accuracy. Maintaining consistent RPM during drilling prevents overheating and reduces tool wear, which boosts both precision and longevity. The ability to quickly adjust speeds is essential when switching between different metals or thicknesses, saving time and effort. Some drill presses feature belt-driven mechanisms that allow smooth, effortless speed changes without interrupting your workflow. Overall, good speed control helps you drill more efficiently while protecting your tools and ensuring better results.

Safety Features and Guards

Safety features and guards are essential considerations when working with a drill press for metalworking, as they safeguard against accidental injuries and guarantee a smoother workflow. I look for safety guards like Lexan shields or metal enclosures that prevent accidental contact with moving parts. Adjustable safety features, such as flip-up shields and repositionable guards, allow me to customize protection without slowing down my work. It’s important that these guards fit the drill press size and are easy to install or remove without extensive modifications. Additional safety features like emergency stop buttons, laser alignment, and clear visibility shields enhance safety and reduce injury risks. Regularly inspecting and maintaining these guards ensures they stay effective and reliable during demanding metalworking tasks.

Precision and Alignment Tools

Ever wondered how to guarantee your drill holes are perfectly aligned and precise? Precision and alignment tools like lasers and digital readouts make that possible. A laser guide with a class IIIA 2.5mW laser helps you accurately position your drill, reducing errors and ensuring consistent results. Digital depth stops and readouts allow you to control the depth of each hole exactly, which is essential for repeatability and quality. Adjustable worktables and tilting features give you the flexibility to angle and position workpieces accurately, even for complex cuts. Reliable alignment tools not only improve accuracy but also enhance safety by maintaining consistent drilling trajectories, preventing misalignment that could cause accidents. Investing in these features makes a real difference in achieving professional, precise metalworking results.

Frequently Asked Questions

How Do I Maintain and Clean My Drill Press Effectively?

To keep my drill press in top shape, I regularly clean it with a brush and compressed air to remove dust and metal shavings. I lubricate the moving parts with appropriate oil and check the belts and pulleys for wear. After each use, I wipe down the table and chuck. This routine makes certain of smooth operation, longevity, and safety during my metalworking projects.

Can I Upgrade Parts on My Existing Drill Press?

Yes, you can upgrade parts on your existing drill press, turning it into a more refined tool like giving a classic car a turbo boost. I’ve replaced motors, upgraded the pulleys, and added better chuck systems myself. Just guarantee compatibility and quality. Think of it as customizing your ride—small tweaks that make a big difference in performance and precision, extending your machine’s lifespan and your satisfaction.

What Safety Gear Should I Wear When Using a Drill Press?

When using a drill press, I always wear safety goggles to protect my eyes from flying debris, and ear protection if noise levels are high. I avoid loose clothing and jewelry that could get caught, and I keep my hands at a safe distance from the spinning bit. Wearing a dust mask is also a good idea if you’re working with materials that produce fine particles. Safety first!

How Do I Troubleshoot Common Drill Press Operational Issues?

When troubleshooting drill press issues, I start by checking the power supply and ensuring the switch is on. If it’s not drilling straight, I inspect the chuck for tightness or wear. For unusual noises, I stop and examine the belt and pulleys for proper alignment. Regular maintenance, like cleaning and lubricating moving parts, helps prevent problems. If issues persist, I consult the user manual or a professional for guidance.

What Are the Best Accessories to Enhance Drill Press Performance?

I recommend adding a quality vise to secure your workpiece firmly, improving accuracy and safety. A drill press table extension can increase your workspace for larger projects, while a coolant system helps reduce heat and wear on bits. Upgrading to a digital readout guarantees precise depth control, and a set of high-quality drill bits enhances performance across different materials. These accessories truly boost your drill press’s efficiency and output.

Conclusion

Choosing the right drill press can boost your metalworking projects considerably. Did you know that a high-quality drill press can increase precision by up to 30%? Whether you’re aiming for power, accuracy, or versatility, I hope this list helps you find the perfect tool. Investing in the right drill press isn’t just about convenience—it’s about elevating your craftsmanship and achieving results that truly stand out. Happy drilling!