Neutral switching in ATS systems is vital for safety, system reliability, and code compliance. It manages how the neutral conductor switches during transfers—either solidly bonded or isolated—affecting ground fault detection and system stability. Choosing the right setup depends on your power sources and application needs. Proper neutral switching prevents ground loops, reduces nuisance trips, and guarantees safe, seamless transfers. If you want to learn more about best practices and common pitfalls, there’s more to explore.

Key Takeaways

- Neutral switching involves dedicated poles that switch the neutral conductor during transfer, ensuring system safety and proper grounding.

- Proper design and component coordination prevent ground faults, nuisance trips, and maintain system reliability during source changes.

- 3-Pole ATS bonds neutral at one point, while 4-Pole ATS switches the neutral, affecting fault detection and grounding practices.

- Switched neutral is essential when using separately derived sources to prevent neutral current flow and ground loop issues.

- Correct wiring, regular inspection, and understanding neutral configurations are critical for safety, compliance, and optimal system performance.

Understanding the Basics of Neutral Switching in ATS Systems

Understanding the basics of neutral switching in ATS systems is essential for ensuring safe and reliable power transfer. An ATS moves electrical loads between two sources, like utility and generator, to maintain power continuity. Neutral switching involves dedicated poles that switch the neutral conductor along with phase conductors during transfer. Since the neutral provides return paths and grounding, switching it properly is vital for safety and system integrity. In systems with separately derived generators, neutral switching isolates the neutral connection to prevent grounding issues and fault currents from causing hazards. This process guarantees the system remains compliant with electrical codes and prevents nuisance trips of ground fault protection. Proper neutral switching guarantees that grounding and fault management stay consistent, maintaining safe operation during source transitions. Neutral switching also plays a crucial role in preventing potential ground loops and ensuring proper system grounding practices are maintained across different power sources. Additionally, understanding how grounding practices interact with neutral switching can help prevent unintended current paths that may lead to equipment damage or safety hazards.

When to Opt for Solid Neutral Configurations

Choosing a solid neutral configuration simplifies your system’s design and can save you money by reducing complexity. If your setup involves a non-separately derived source or a straightforward backup, this approach keeps things straightforward and cost-effective. However, make sure your system’s grounding and bonding meet the requirements to avoid potential issues. Neutral wiring may be omitted if no loads downstream require a neutral connection, further streamlining the installation. Understanding industry trends in power system configurations can help ensure your setup adheres to current best practices.

Simplicity in Design

When is it best to opt for a solid neutral configuration in an ATS design? It’s ideal when the generator neutral isn’t separately grounded and can be integrated into the building’s common neutral system. This setup simplifies wiring since only the hot conductors switch, leaving the neutral permanently bonded. It’s suitable when generator and utility neutrals are bonded, avoiding complex transfer mechanisms. Use it when fault currents won’t cause safety issues or code violations, and the neutral remains continuous during transfer. Additionally, understanding neutral bonding is crucial for safety and system integrity.

Cost-Effective Setup

Opting for a solid neutral configuration in an ATS can considerably reduce installation costs by simplifying the switch and wiring requirements. With fewer poles needed—typically just three for three-phase systems—you cut hardware expenses and streamline assembly. The generator and utility neutrals are permanently bonded inside the ATS, eliminating extra neutral switching components. This approach also reduces labor during installation and maintenance due to less complex wiring. It’s especially cost-effective when your generator isn’t separately derived, avoiding the need for additional neutral bonding or control wiring. Additionally, solid neutral designs eliminate extra components like neutral-to-ground links, lowering material costs. Kia Tuning techniques can sometimes be integrated into the electrical setup for optimized efficiency.

- Fewer poles decrease switch and hardware expenses

- No additional neutral switching components required

- Simplified wiring reduces labor costs

- Suitable for non-separately derived generator systems

- Eliminates extra neutral-to-ground bonding hardware

The Situations That Call for Switched Neutral ATS

Situations involving separately derived power sources, such as generators not bonded to the utility neutral, require a switched neutral Automatic Transfer Switch (ATS) to prevent neutral currents from flowing between systems. Without neutral switching, parallel neutral paths can cause ground loop issues, false tripping of ground-fault protection devices, or unwanted electrical noise. This setup is essential in applications with ground-fault protection requirements, like healthcare or industrial environments, where nuisance trips could jeopardize safety. Additionally, complex power systems with multiple sources or critical loads, such as data centers or hospitals, benefit from neutral switching to maintain load stability and ensure proper protection coordination. Proper neutral switching design is crucial to ensure system reliability and safety in these complex configurations. Ensuring compliance with electrical codes helps prevent violations and enhances overall safety by preventing neutral-related faults and system interference.

How Neutral Switching Enhances System Safety and Compliance

Neutral switching enhances system safety and compliance by providing electrical isolation between power sources, which reduces the risk of dangerous currents flowing between utility and generator systems. This isolation helps prevent neutral currents from circulating, minimizing potential equipment damage and electrical hazards. It also supports ground fault protection by enabling accurate fault detection, ensuring safety standards are met. Proper neutral switching reduces nuisance trips caused by unbalanced loads, keeping systems stable. Additionally, it guarantees compliance with electrical codes like NEC, which mandates neutral switching in certain setups. The use of robust neutral switch contacts handles fault currents effectively, maintaining safety during ground faults. Understanding creative practice can also help engineers develop innovative solutions for complex electrical systems.

Neutral switching ensures safety, reduces equipment damage, and guarantees compliance with electrical standards.

- Ensures accurate ground fault detection

- Prevents neutral current circulation

- Meets NEC and safety standards

- Reduces equipment wear and damage

- Supports reliable system operation

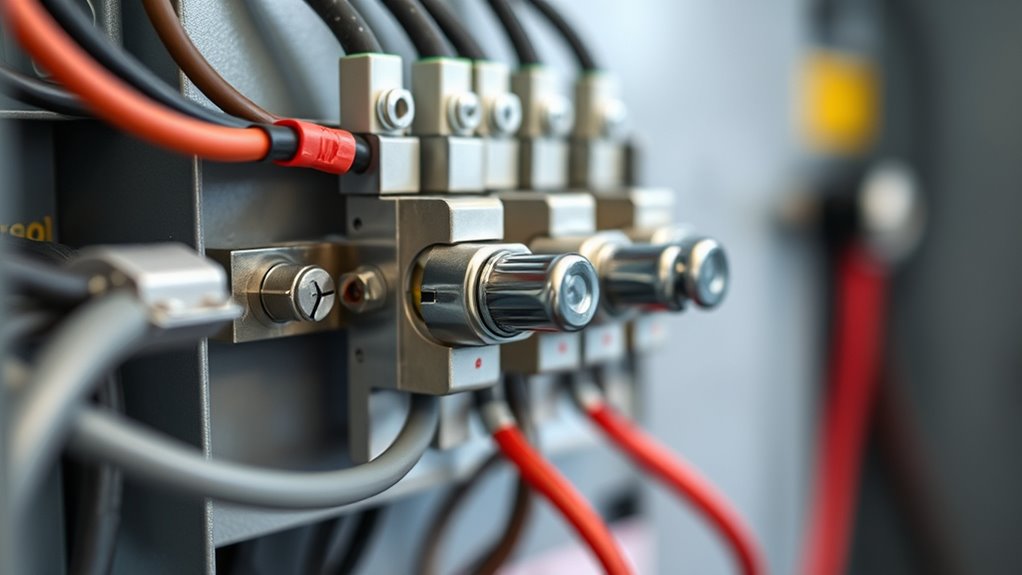

Key Components of Neutral Switching in Automatic Transfer Switches

The core component of neutral switching in automatic transfer switches is the fully rated neutral pole, which operates in tandem with the phase poles during source transfer. This neutral pole is typically a dedicated contactor designed to handle fault currents and guarantee reliable operation. It can be configured for break-before-make or make-before-break switching, depending on system needs. The neutral contactor opens or closes simultaneously with the phase contacts to prevent circulating currents or ground faults. In some systems, a bypass isolation switch allows maintenance without load interruption, integrating neutral switching functionality. Additionally, proper neutral bonding and grounding are vital for safety and compliance. The neutral pole’s design ensures it can safely handle fault conditions and maintain system integrity during transfers. Proper coordination of these components is essential to avoid ground fault issues and ensure seamless power transfer. Together, these components ensure the neutral conductor’s safe, coordinated transfer, maintaining system integrity and protecting against ground faults during source changes.

Comparing Three-Pole and Four-Pole ATS for Neutral Management

When choosing between three-pole and four-pole ATS, you need to take into account how they handle neutral connections and system grounding. The three-pole design keeps the neutral bonded at one point, while the four-pole switches the neutral to meet specific grounding requirements. Understanding your system’s application helps determine which approach ensures reliable operation and compliance. Additionally, being aware of vetted safety standards for electrical components can guide proper selection and installation.

Neutral Connection Methods

Choosing between three-pole and four-pole Automatic Transfer Switches (ATS) for neutral management hinges on your system’s configuration and safety requirements. With a three-pole ATS, the neutral remains continuous, bonded to ground at one point, typically the utility. In contrast, a four-pole ATS switches the neutral conductor along with the phases, suitable for 3-phase, 4-wire systems where neutral switching is essential. Four-pole configurations treat each source as separately derived, bonding neutrals independently. 3-Pole ATSs are generally less complex, making them suitable for many backup power applications, especially when the system’s ground fault sensing rules are met. – Three-pole ATS simplifies system design and reduces cost but maintains a single neutral-to-ground bond. – Four-pole ATS provides neutral switching, preventing parallel neutral paths and ensuring safety. – Proper neutral management avoids ground faults and interference. – Consistency in neutral connection methods across all ATS units enhances reliability. – Neutral switching is critical when sources have separate neutral-ground bonds, especially in emergency systems. Additionally, neutral management is vital for preventing ground faults and maintaining power system stability.

System Grounding Strategies

System grounding strategies differ markedly between three-pole and four-pole ATS configurations, especially regarding how neutrals are managed. In a three-pole setup, the neutral remains solidly bonded at a single point, typically the utility, with no switching, simplifying ground-fault protection. Conversely, four-pole ATS switches the neutral alongside the phases, isolating neutrals between sources and enabling separate ground bonds. This approach prevents circulating currents and allows distinct fault detection. The table below highlights key differences:

| Feature | 3-Pole ATS | 4-Pole ATS | Impact |

|---|---|---|---|

| Neutral Switching | No | Yes | Better fault isolation |

| Ground Bonding | Single point | Multiple points | More complex protection |

| Cost | Lower | Higher | Budget considerations |

| System Type | Non-separately derived | Separately derived | System design flexibility |

| Fault Detection | Simpler | More complex | Enhanced reliability |

Choosing the right system depends on your application’s grounding and fault management needs. Additionally, understanding the main advantage of four-pole switching—namely, improved fault detection—is essential for designing a reliable power system.

Application Suitability

Three-pole ATS are ideal for applications where the system isn’t separately derived, meaning there’s only one neutral-to-ground bond point. They’re suitable for simpler setups with a solid neutral that remains continuous during source transfer. Use a three-pole ATS when neutral switching isn’t required, reducing system complexity and costs. This setup works well if ground fault detection is downstream or on the load side and the system design doesn’t demand neutral disconnection during switching. Utilizing vertical storage solutions can help organize electrical components and improve overall system accessibility.

Common Mistakes and Pitfalls in Neutral Switching Applications

Neutral switching applications are prone to several common mistakes that can compromise safety, system reliability, and code compliance. Wiring errors are frequent, such as connecting neutrals to the wrong panel or failing to properly wire nut neutrals during transfers, which can cause current imbalance and voltage issues. Confusing solid neutral connections with switched neutrals may lead to unpredictable system behavior during transfers or faults. Returning neutrals without proper separation can also create neutral current issues. Load and equipment selection mistakes, like underestimating inrush currents or choosing an undersized ATS, risk overload and failure. Neglecting regular maintenance, such as cleaning contacts or verifying neutral switch operation, increases failure risk. Finally, switching neutrals without considering fault ratings or proper grounding can pose serious safety hazards and violate codes. Understanding system grounding and proper wiring practices is essential to prevent these issues and ensure safety.

Impact of Neutral Switching on Grounding and Fault Protection

Switching the neutral conductor in an automatic transfer switch (ATS) considerably impacts ground fault detection and protection. A four-pole ATS isolates the neutral, creating a separately derived system with its own neutral-to-ground bond, enhancing fault detection accuracy. Conversely, a three-pole ATS keeps the neutral solidly connected, which can mask ground faults or cause nuisance trips. Proper neutral switching guarantees a single, controlled fault path, improving sensing and trip reliability. Misapplication can lead to unbalanced loads or False trips, reducing system stability. Incorporating mindfulness in system design and maintenance can help operators remain attentive to potential issues and ensure optimal performance.

Best Practices for Installing and Maintaining Neutral Switching Systems

Proper installation and maintenance of neutral switching systems are essential to guarantee safe and reliable operation. First, choose a location near the main electrical panel for easy wiring and access. Confirm the area is dry, spacious, and compliant with local codes. Use the manufacturer’s mounting hardware and secure the switch firmly to prevent movement. During installation, always shut off the main power and verify wires are de-energized with a voltage tester. Wear insulated gloves and goggles for safety. Follow wiring instructions carefully, especially for neutral and ground connections. Regularly inspect contacts and mechanisms, testing the system under load. Keep detailed records. Proper wiring is critical to ensure system safety and performance. Use the table below to guide your setup and maintenance:

| Best Practice | Purpose |

|---|---|

| Proper location and secure mounting | Safety, ease of access, stability |

| Confirm de-energized wiring | Prevent shocks, ensure safety |

| Routine inspection and testing | Reliability, early fault detection |

| Documentation of maintenance | Troubleshooting, compliance |

Real-World Scenarios Demonstrating Neutral Switching Benefits

Implementing neutral switching in Automatic Transfer Switch (ATS) systems can substantially enhance safety, reliability, and equipment longevity in real-world applications. By switching neutrals, you prevent potential shock hazards, reduce equipment damage risks, and ensure compliance with standards like NEC Articles 700-702. This approach also prevents neutral ground conflicts, avoiding circulating currents and voltage imbalances that can disrupt system stability. Additionally, neutral switching protects sensitive equipment such as UPS and data centers from erratic neutral voltages, reducing downtime and maintenance. It facilitates seamless source transitions, minimizing transfer times and ensuring continuous power for critical loads. Track development techniques are crucial for creating dependable and effective neutral switching solutions.

Frequently Asked Questions

How Does Neutral Switching Affect Overall System Grounding and Safety?

Neutral switching improves your system’s grounding and safety by isolating the neutral connections, preventing multiple grounding paths that can cause faults to go unnoticed. It guarantees the generator operates as a separate source, reducing electrocution risks and maintaining proper ground fault detection. With neutral switching, you comply with electrical codes, enhance personnel safety, and facilitate safer maintenance, because it eliminates unintended grounding and provides clear fault pathways for protective devices.

Can Solid Neutral Systems Cause Issues in Multi-Source Backup Configurations?

Solid neutral systems can cause issues in multi-source backup setups by creating parallel return paths for fault currents, which may bypass ground fault detection. This can lead to false trips or missed faults, especially if neutrals aren’t properly isolated or switched. Additionally, solid neutrals can complicate grounding, increase nuisance tripping, and interfere with protective device coordination, making your system less reliable and harder to maintain safely.

What Are the Code Compliance Considerations for Neutral Switching in ATS?

Think of code compliance as the roadmap guiding your system’s safety. You must guarantee your ATS with neutral switching follows NFPA 110 and NEC 250 standards. This means using listed transfer switches, properly sizing neutral conductors, and avoiding dual neutral-to-ground bonds in separately derived systems. Also, document your setup clearly to prevent confusion during inspections. Staying aligned with these codes keeps your system safe, reliable, and compliant.

How Do I Determine if My System Requires Switched or Solid Neutral ATS?

To determine if you need a switched or solid neutral ATS, first check if your generator neutral is separately grounded or common to the utility system. If it’s separately grounded, you likely need a switched neutral ATS to avoid neutral-to-ground conflicts. If the neutral is continuous and bonded only at the utility, a solid neutral ATS usually suffices. Confirm your grounding setup and system configuration before making a decision.

What Maintenance Is Necessary for Neutral Switching Components in ATS?

You need to regularly inspect and clean the neutral switching components, checking for arcing, corrosion, or debris buildup. Test the mechanical operation to ensure smooth engagement and measure contact resistance for signs of wear. Confirm proper grounding and verify contact alignment and pressure. Follow manufacturer guidelines for maintenance schedules, promptly replace worn parts, and document all activities. Proper maintenance guarantees reliable neutral switching, enhances safety, and prolongs your ATS’s lifespan.

Conclusion

Understanding neutral switching in ATS systems is vital for safety and compliance. Did you know that improper neutral configurations can increase fault risks by up to 30%? By mastering these concepts, you guarantee reliable power transfer and protect your systems from costly failures. Keep the best practices in mind, stay vigilant during installation, and you’ll reap the safety and efficiency benefits that neutral switching offers. Your systems will thank you for it.