To avoid issues with your generator, guarantee proper clearances, like maintaining at least 36 inches on ends and 60 inches above for heat dissipation. Design ventilation systems considering heat and emission control, and keep exhaust outlets properly placed away from air intakes and occupied spaces. Regular maintenance, compliance with standards, and awareness of environmental factors are key. Stay ahead of these common mistakes to keep your system safe and efficient—more tips await if you continue exploring.

Key Takeaways

- Maintain minimum clearance distances (e.g., 36 inches at ends, 5 feet from openings) for safe operation and maintenance access.

- Design ventilation systems with proper airflow, heat management, and emission control measures to prevent overheating and gas buildup.

- Regularly inspect and service critical components, ensuring compliance with NFPA 110 and local safety standards.

- Position exhaust outlets and stacks correctly, considering wind patterns and regulatory height requirements to prevent gas recirculation.

- Clear vegetation and obstructions around the generator area to ensure unobstructed airflow and compliance with safety guidelines.

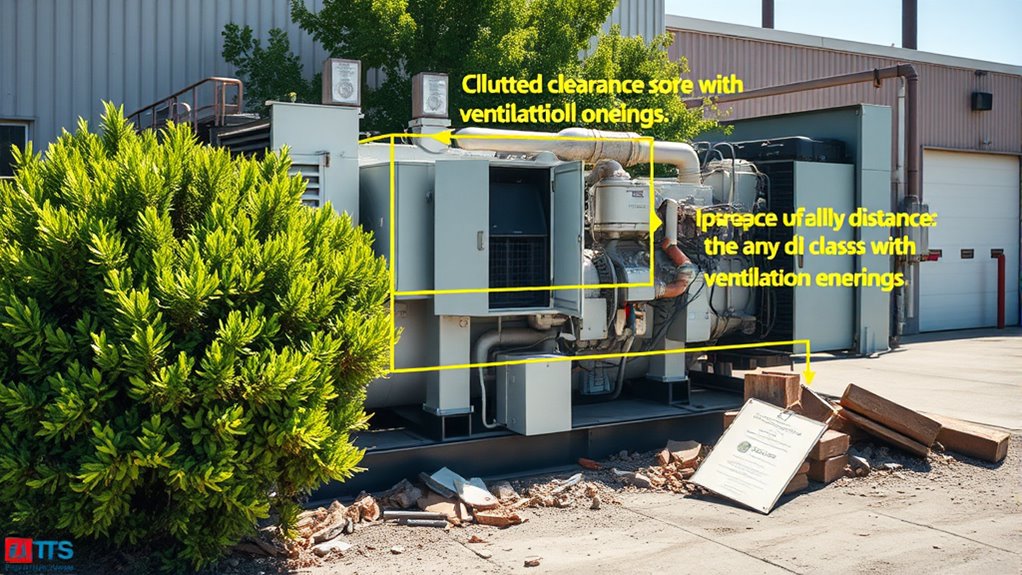

Overlooking Proper Clearance Distances Around Generators

Ensuring proper clearance distances around your generator is essential for safe operation and easy maintenance. You should keep at least 36 inches from the ends and front of your generator to allow safe service access and airflow. This space also helps prevent obstructions like shrubs or trees from blocking ventilation or access points. A minimum of 3 feet 6 inches is necessary for door openings, ensuring you can service the unit without restrictions. Additionally, maintain at least 5 feet of clearance from operable windows, doors, or other openings to prevent exhaust fumes from entering buildings. Clearances above the generator should be at least 60 inches to promote proper heat dissipation and airflow. Regular clearance inspections are vital to ensure ongoing safety and compliance with local codes. Properly maintaining these clearances minimizes safety hazards and optimizes your generator’s performance during operation and maintenance, especially considering airflow requirements for efficient cooling. Adhering to these distances minimizes safety hazards and optimizes your generator’s performance during operation and maintenance.

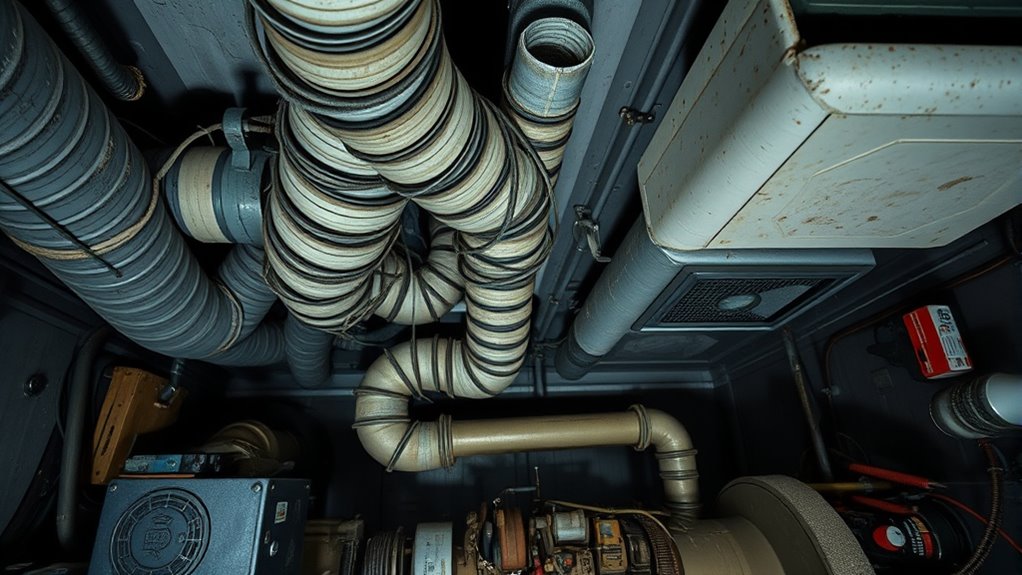

Designing Ventilation Systems Without Considering Heat and Emission Control

If you ignore heat management and emission control when designing ventilation, your generator room can overheat or accumulate harmful pollutants. Proper strategies are vital to prevent equipment damage, guarantee safety, and maintain efficiency. Failing to plan for these factors risks costly repairs and unsafe operating conditions. Incorporating appropriate ventilation techniques can significantly improve heat dissipation and pollutant removal, ensuring optimal performance and safety.

Heat Management Strategies

Designing ventilation systems without considering heat and emission control can lead to serious issues like equipment overheating and reduced lifespan. To prevent this, size your ventilation based on your generator’s make, size, and room specifics. Guarantee airflow removes radiant engine and alternator heat, while providing enough combustion air. Increase ventilation capacity by about 10% for every 2,500 feet above sea level to account for air density changes. Position air inlets low to cover the entire generator and discharge vents high to avoid hot air recirculation. Use CFD modeling for complex layouts, and incorporate dampers for airflow regulation. Effective heat removal relies on directing airflow from alternator to engine, wrapping exhaust piping to reduce radiant heat, and maintaining room layout to prevent hot spots. Proper heat management prolongs generator life and improves efficiency. Additionally, implementing proper ventilation design principles ensures optimal airflow distribution and prevents localized overheating, further enhancing the longevity and performance of your generator.

Emission Control Measures

Neglecting emission control considerations when planning ventilation systems can lead to serious safety and compliance issues. Without proper design, hazardous gases like carbon monoxide and nitrogen oxides can accumulate, risking health and regulatory violations. To avoid these problems, guarantee your system:

- Provides alarms for fan failures or airflow blockages to prevent dangerous buildup

- Uses fire-resistant materials in ducts to reduce fire risks from heat and exhaust

- Draws outside air directly, without dampers that could compromise fire ratings

- Monitors temperature and airflow with sensors, triggering alarms for any failures or blockages

- Ensures proper maintenance and regular inspections to sustain effective emission control and airflow management which is essential for NFPA 110 compliance.

- Incorporate proper ventilation design principles to optimize airflow and prevent stagnation that could exacerbate emission issues.

Blocking Airflow With Nearby Structures or Vegetation

Nearby structures and dense vegetation can substantially obstruct a generator’s airflow, impairing its ventilation and cooling capabilities. Buildings, walls, and foliage close to the generator can block intake and exhaust paths, reducing airflow and increasing heat buildup. Walls should be kept at least 3 feet away, and openings like windows or vents should be at least 5 feet from the generator to prevent exhaust recirculation. Vegetation such as trees, shrubs, and leaves can physically block air movement, trap dust, and promote corrosion. Branches near exhaust outlets may cause emissions to re-enter the intake, degrading air quality. Regular clearing of vegetation and maintaining proper clearances are essential. Proper placement ensures unobstructed airflow, helping your generator run efficiently and safely while minimizing maintenance needs. NFPA 37 emphasizes that exhaust locations must prevent re-entrainment to ensure safe operation. Additionally, choosing a location with good air circulation can further enhance performance and longevity of the generator.

Incorrect Placement of Exhaust Stacks and Emission Outlets

Proper placement of exhaust stacks and emission outlets is essential to guarantee safe and efficient generator operation. If you don’t position stacks at least 25 feet from air intakes, you risk contaminating indoor air and exposing occupants to harmful gases. Ensure stacks discharge vertically and unobstructed to prevent downwash effects that could channel exhaust toward windows, doors, or people. Consider prevailing winds to avoid recirculation of gases back into the building or nearby structures. Additionally, adhering to safety standards and local codes helps ensure compliance and optimal performance. Be mindful of these points:

Properly position exhaust stacks at least 25 feet from air intakes for safe, efficient generator operation.

- Keep exhaust outlets away from occupied areas and sensitive receptors

- Install stacks at heights complying with regulations, often above roofs or building height

- Use vertical, unobstructed discharge to optimize plume rise

- Consider nearby structures that could create turbulence or downwash

Failing to Maintain Optimal Environmental Conditions Inside Generator Rooms

Maintaining the right environmental conditions inside your generator room is vital for reliable operation and longevity. Temperature should stay between 18°C and 27°C to prevent overheating and reduce engine wear. Excess heat from the generator, exhaust, and other equipment can cause critical failures if not managed properly. Design your cooling systems, including radiators and ventilation, to handle maximum heat loads. Proper airflow is essential; supply fresh air for cooling and exhaust hot, contaminated air without recirculation. Keep ventilation openings unobstructed and ensure backup systems activate automatically during failures. Additionally, regulate humidity between 40% and 60% to prevent corrosion and electrical issues. Regularly monitor air quality to avoid buildup of fumes, dust, and pollutants that can damage your generator and compromise safety. Proper ventilation design ensures optimal environmental conditions inside the room, directly impacting equipment performance and safety. Implementing ventilation control systems can further optimize airflow and environmental stability.

Ignoring Regulatory Standards and Routine Maintenance Requirements

Ignoring regulatory standards and routine maintenance can lead to serious safety and compliance issues. When you neglect inspections and documentation, small problems can escalate into system failures or violations. Staying proactive guarantees your generator ventilation system remains safe, efficient, and fully compliant. Regular maintenance according to NFPA 110 standards is essential for ensuring all components function properly and meet safety requirements. Additionally, understanding and adhering to local building codes and permit requirements helps prevent legal consequences and ensures the system’s integrity.

Regulatory Compliance Oversights

Regulatory compliance is essential for ensuring your generator ventilation systems operate safely and effectively, but it’s easy to overlook critical standards and routine maintenance requirements. Missing these can lead to safety hazards, fines, or system failures. To stay compliant, you should:

- Regularly verify that ventilation maintains ambient temperatures within manufacturer limits.

- Ensure alarms and temperature monitoring are functional and integrated into remote alert systems.

- Keep air inlets and outlets free from blockages and properly sized.

- Use fire-resistant materials for ducts, dampers, and other components.

- Adhering to local and international standards is crucial, as non-compliance may result in costly legal actions and operational delays.

Ignoring these requirements risks compromised safety, environmental violations, and costly downtime. Staying on top of compliance helps you avoid penalties, ensures reliable operation, and protects your facility’s reputation. Regular checks and adherence to standards are your best defense.

Maintenance Neglect Risks

Neglecting routine maintenance and regulatory standards can seriously compromise your generator’s reliability and safety. Over time, engine and cooling system degradation occurs if you skip oil changes, causing overheating and engine damage. Dirty filters make the engine work harder, increasing failure risk, while low coolant levels and incorrect temperature regulation worsen overheating and wear. Failing to replace contaminated lubricants accelerates component deterioration. Fuel system neglect leads to microbial growth, debris buildup, and water contamination, which clog filters and impair performance. Neglecting battery maintenance causes startup failures and electrical issues, risking operational downtime. Skipping regular inspections, load testing, and filter replacements allows contaminants to damage the engine and electrical parts. Poor maintenance practices markedly raise failure rates, reduce lifespan, and threaten safe generator operation. Lack of Regular Maintenance can also lead to increased operational costs due to inefficient fuel use and unanticipated repairs. Additionally, neglecting proper device compatibility and connection procedures may cause communication issues or damage when integrating with control systems.

Inspection and Documentation

Regularly inspecting your generator’s ventilation and maintaining thorough documentation are essential to guarantee safe and reliable operation. Proper inspections help identify issues before they escalate, and detailed records support compliance and troubleshooting. Focus on:

- Checking for blockages, cracks, or leaks in radiator, fan, belts, and air filters that impede airflow

- Verifying coolant levels and inspecting the block heater for proper engine temperature management

- Testing batteries for secure mounting, corrosion, electrolyte levels, and charge retention

- Confirming exhaust system components operate correctly, venting fumes away from enclosed areas

- Ensuring generator testing and maintenance are documented accurately, including inspection dates and findings, to facilitate ongoing compliance and troubleshooting efforts which is critical for NFPA 110 compliance. Regular adherence to regulatory standards helps prevent potential hazards and ensures safe operation.

Accurate documentation should include test dates, operator signatures, operating conditions, and any corrective actions taken. Maintaining logs for at least three years ensures accountability, aids trend analysis, and helps meet regulatory standards.

Neglecting the Impact of Local Environmental Factors on Ventilation Design

Understanding and accommodating local environmental factors is essential for effective generator ventilation design because these conditions directly influence airflow requirements and system performance. High ambient temperatures increase overheating risks, so you need enhanced cooling systems to prevent damage and maintain efficiency. Cold climates cause fuel thickening, requiring preheating or additives to ensure proper combustion. Humidity can lead to corrosion and incomplete fuel burning; ventilation must promote fresh air exchange to optimize air-fuel ratios and reduce emissions. At higher altitudes, reduced air density affects combustion, demanding adjustments in airflow and fuel delivery. You also must consider site-specific hazards like prevailing winds, flood zones, and noise regulations to avoid re-circulating hot exhaust or compromising ventilation. Ignoring these factors can result in poor performance, increased wear, and safety hazards. Additionally, local environmental conditions can influence the choice of ventilation equipment and materials, ensuring durability and effectiveness over time. Moreover, understanding dog breed characteristics can help tailor the ventilation and safety measures to specific operational needs.

Frequently Asked Questions

How Do Local Building Codes Influence Clearance and Ventilation Requirements for Generators?

Your local building codes shape how you install your generator by setting minimum clearance and ventilation standards. They often require specific distances from structures, openings, and combustibles, and may mandate facing exhaust away from buildings. You need to follow manufacturer instructions, obtain permits, and have inspections to guarantee compliance. Regional variations might mean stricter or more lenient requirements, so always check your local regulations to avoid delays or violations.

What Are the Environmental Considerations Affecting Exhaust Stack Placement and Height?

You should prioritize environmental factors because improper stack placement can lead to harmful pollutant concentrations near sensitive areas. For instance, stacks must discharge vertically to prevent air pollution, reducing ground-level concentrations that affect nearby residents and open spaces. You also need to contemplate local wind patterns and topography, ensuring exhaust gases disperse effectively. Proper height and positioning minimize health risks, meet regulations, and help protect outdoor air quality.

How Can Vegetation and Nearby Structures Be Managed to Optimize Airflow?

You can optimize airflow by trimming or removing vegetation within 3 feet of your generator, guaranteeing low-growing plants or non-combustible landscaping. Keep structures at least 60 inches away to prevent airflow restrictions and avoid placing the generator under decks or near walls that could cause turbulence. Regularly inspect the area, maintain clearances, and follow manufacturer guidelines to ensure proper ventilation and prevent overheating.

What Are the Best Practices for Maintaining Indoor Generator Room Environmental Conditions?

Maintaining indoor generator room conditions is like tending a delicate garden—constant attention is key. You should regularly monitor and control temperature, ensuring it stays within manufacturer specs. Keep ventilation pathways clear of obstructions, and ensure intake and exhaust systems are properly sized and positioned to prevent heat and fumes buildup. Use high-quality filters, and follow safety standards like NFPA 110 to uphold ideal air quality and safety.

How Often Should Ventilation and Exhaust Systems Be Inspected and Maintained?

You should inspect and maintain your ventilation and exhaust systems at least annually, or more frequently if your generator runs heavily or in harsh environments. Regular checks ensure vents are clear of debris and exhaust pathways are unobstructed, preventing dangerous buildup. Schedule professional inspections during your routine generator servicing, especially before peak seasons, to guarantee proper airflow, reduce risks of overheating, and keep your system running safely and efficiently.

Conclusion

To keep your generator running smoothly, don’t overlook these common mistakes—think of your ventilation system as the lungs of your setup. Just like breathing deeply keeps you energized, proper clearances, airflow, and maintenance ensure ideal performance and safety. Avoid blocking vents or ignoring regulations, because neglecting these can be as disastrous as trying to breathe through a clogged straw. Stay proactive, stay compliant, and give your generator the fresh air it needs to thrive.