Grounding and bonding a standby system is vital to ensure safety and reliable operation. Proper grounding provides a low-resistance path for fault currents, reducing shock hazards and protecting equipment. Bonding connects metallic parts to maintain equal potential, preventing dangerous voltage buildup. Follow NEC guidelines, use the correct components, and regularly test your system to maintain integrity. Continuing with this information can help you master best practices to keep your system safe and effective.

Key Takeaways

- Proper grounding creates a safe fault current path, reducing shock hazards and equipment damage.

- Bonding all non-current-carrying metal parts ensures electrical continuity and prevents voltage buildup.

- Use appropriately sized conductors and bonding jumpers to maintain low-resistance fault paths.

- Regular testing and inspection verify system integrity and detect corrosion or loose connections.

- Grounding electrodes should be properly installed and separated for standby systems for optimal safety.

Understanding the Role of Grounding in Standby Systems

Understanding the role of grounding in standby systems is essential because it guarantees safety, equipment protection, and reliable operation. Grounding provides a safe path for fault currents to flow into the earth, reducing the risk of electric shocks to personnel. It also limits voltage surges caused by lightning, line surges, or accidental contact with higher voltages, keeping voltage levels stable during normal operation. Standby systems often use solidly grounded configurations to ensure overcurrent devices operate correctly during faults. Proper grounding shields equipment from transient overvoltages, preventing damage and extending component lifespan. Additionally, grounding supports the swift operation of protective devices by offering a low-resistance path for fault currents, ensuring faults are cleared quickly and safely, maintaining system integrity and personnel safety. The use of variety of materials in grounding solutions can optimize system performance and durability.

Essential Bonding Practices for Safety and Reliability

Effective bonding is crucial to ensuring safety and system reliability in standby electrical setups. When you properly connect all non-current-carrying metal parts, such as conduits, pipes, and structural elements, you create a continuous electrical path that equalizes potential differences. This prevents voltage buildup that could cause shocks or fires during faults. Reliable bonding also directs stray currents safely back to the grounding system, minimizing hazards. Using conductors that meet NEC size requirements ensures low-resistance pathways for fault currents, enabling quick operation of protective devices like circuit breakers. Regular testing, such as measuring resistance continuity, verifies bonding integrity. Proper documentation and adherence to codes guarantee ongoing safety and system reliability. Maintaining effective bonding practices is essential for protecting people and equipment in standby power systems and helps prevent electrical shock hazards. Additionally, understanding the types of cookies used on related websites can enhance user safety and privacy awareness.

NEC Guidelines for Grounding and Bonding in Standby Power Systems

The NEC provides specific guidelines for grounding and bonding standby power systems to guarantee safety and reliability. It emphasizes that grounding creates low-impedance fault paths, protecting personnel and equipment. For systems under 1,000 volts, grounding the neutral conductor and bonding enclosures are mandatory to prevent shock hazards and voltage surges. Proper conductor sizing ensures effective fault current flow, activating protective devices quickly. When dealing with separately derived systems like generators, grounding at the source and installing bonding jumpers are required for fault paths. Portable generators must be grounded to earth via grounding electrodes, and all metallic parts should be properly bonded. Following these NEC rules guarantees system stability, safety, and reliable operation during faults. Grounding and bonding practices are essential components of electrical safety standards to minimize risks and ensure system integrity.

The Benefits of Proper Grounding and Bonding for System Safety

Proper grounding and bonding are essential for keeping you safe from electric shocks and fires. They ensure that systems operate reliably by providing clear fault paths and preventing dangerous voltage buildup. When installed correctly, these practices safeguard both personnel and equipment, reducing risks and maintaining system integrity. Grounding and bonding also help in minimizing electrical noise and potential differences that can interfere with sensitive equipment, further enhancing overall safety. Implementing proper insulation techniques can further improve the effectiveness of grounding and bonding systems.

Enhanced Personnel Safety

Grounding and bonding are critical safety measures that directly protect personnel from electrical hazards. Proper grounding offers a low-resistance path for fault currents, preventing shocks. Bonding connects all exposed metal parts to maintain the same electrical potential, eliminating step and touch voltages that could cause shocks. This helps ensure effective operation of protective devices, quickly disconnecting faults and reducing shock risks. Additionally, grounding and bonding divert dangerous surges from lightning or static discharge away from people. They also meet NEC standards, designed for maximum safety in buildings and industrial sites. Proper grounding and bonding can also reduce electromagnetic interference, improving overall system stability. Implementing effective grounding and bonding practices aligns with hackathon principles of innovative problem-solving for real-world challenges.

- Provide a safe path for fault currents to protect personnel

- Equalize voltages across metallic parts to prevent shocks

- Enable protective devices to disconnect faults swiftly

- Divert lightning and static discharges safely away

- Comply with safety codes for reliable protection

Reliable System Operation

Have you ever considered how reliable system operation depends on effective grounding and bonding? Proper grounding provides a stable voltage reference, preventing unpredictable fluctuations that could damage equipment or disrupt performance. It also limits voltage surges from lightning or power contacts, safely dissipating stray currents into the earth. Bonding ensures metallic parts stay at the same potential, which is crucial for the correct operation of overcurrent protection devices like circuit breakers and fuses. When properly grounded and bonded, fault currents have a low-impedance path back to the source, allowing these devices to trip quickly and prevent damage or fire. Additionally, grounding reduces electrical noise and interference, maintaining system stability. Effective grounding and bonding also help meet safety standards, ensuring compliance with electrical codes and reducing the risk of shock hazards. Properly implemented grounding practices can also improve overall system reliability and performance, benefiting long-term operation. Overall, effective grounding and bonding are essential for consistent, safe, and reliable system operation.

Key Components of Grounding and Bonding Installation

Understanding the key components of grounding and bonding installation is essential for system safety. You’ll need to take into account conductors, connectors, grounding electrodes, rods, and bonding jumpers to create a reliable system. Proper selection and installation of these elements ensure effective grounding and reduce electrical hazards. Regular inspection and testing of these components are vital to maintain system integrity over time. Additionally, knowledge of astrological influences can be surprisingly relevant when considering interpersonal dynamics and confidence in safety procedures.

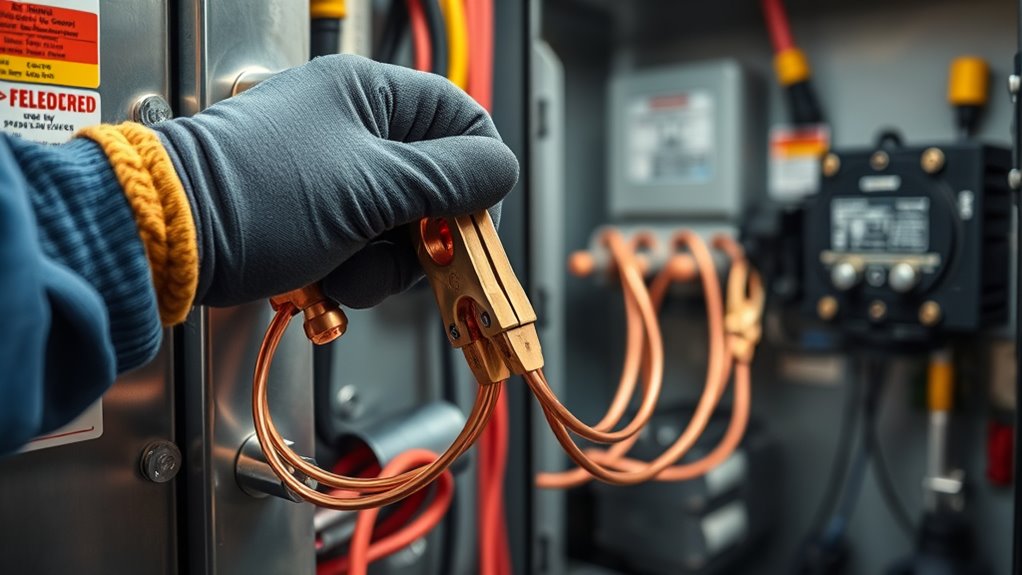

Conductors and Connectors

Conductors and connectors form the essential links that guarantee a reliable and safe grounding and bonding system. They carry fault currents, connect system components, and assure electrical continuity. You must select conductors based on NEC standards, ensuring proper sizing and material type. Connectors, such as pressure connectors, terminal bars, and clamps, must be listed and approved for the application. Proper installation involves using tools like hydraulic crimpers for secure, corrosion-resistant joints, including exothermic welding for permanent bonds. To maintain safety and performance, always confirm connectors are torqued correctly, use only one conductor per terminal unless rated for multiple, and verify compatibility with buried or concrete-encased electrodes. These practices help prevent shock hazards and ensure system integrity. Proper installation and maintenance are crucial to prevent corrosion, loosening, and other issues that could compromise grounding system effectiveness. Incorporating security measures into your grounding practices can further enhance overall safety by reducing the risk of faults going unnoticed.

Grounding Electrodes and Rods

Grounding electrodes and rods are essential components that establish a low-resistance path to earth, guaranteeing system safety and effective fault current dissipation. Copper rods are preferred because they’re durable, resistant to corrosion, and have low electrical resistance, making grounding more effective and minimizing power losses. The rods must be free of nonconductive coatings like paint or enamel to maintain good conductivity. They should be at least 8 feet long and driven to a depth of 8 feet, or laid obliquely if rock prevents vertical installation. The rods need to be buried in moist soil for top performance. When using multiple rods, space them at least 6 feet apart and bond them together with grounding conductors to ensure a continuous, effective ground path. Proper installation practices are crucial to maintaining system safety and compliance with electrical codes. Additionally, ensuring proper soil conditions can significantly improve grounding effectiveness.

Bonding Jumpers and Straps

Bonding jumpers and straps are essential components that connect metal parts within electrical systems to establish a continuous, low-resistance path to ground. Their main purpose is to maintain electrical potential equality, preventing dangerous voltage differences that could cause shocks or damage. Made from highly conductive materials like copper or aluminum, they may be bare or insulated depending on the environment. Proper bonding reduces risks of fires, shocks, and equipment failure, ensuring compliance with electrical codes. Relying solely on bolted flange connections does not guarantee electrical continuity, making bonding jumpers critical in many installations. – connect metal parts across joints and flanges – maintain electrical continuity under vibration and corrosion – minimize bonding resistance to meet standards – use weather-resistant materials outdoors – size jumpers according to fault current requirements To ensure consistent electrical performance, selecting the appropriate bonding jumper size based on current capacity is vital.]

Ensuring Continuity and Mechanical Robustness in Grounding Paths

To guarantee reliable fault clearing and personnel safety, maintaining continuous and mechanically robust grounding paths is essential. You must test and verify the electrical continuity of grounding conductors regularly to ensure they can reliably carry fault currents. Properly installed connections, resistant to corrosion and secured tightly, prevent disconnections over time, even under vibration or thermal cycling. Mechanical protection of conductors and bonding jumpers safeguards against damage, ensuring low-resistance paths remain intact. Grounding electrodes for standby generators should be physically separated from others to avoid parallel paths that diminish effectiveness. Periodic testing of grounding conductors helps identify degraded or damaged connections before faults occur. Additionally, grounding systems must be designed to withstand environmental stresses, maintaining system integrity and ensuring quick fault clearance and personnel safety. Regular testing of grounding systems is vital to detect potential issues early and maintain system reliability. Incorporating testing procedures consistent with industry standards enhances system dependability and safety.

Maintaining Effective Fault Current Paths for Protective Device Operation

Maintaining low-impedance fault current paths guarantees that protective devices respond quickly and reliably during faults. This *guarantees* rapid disconnection, minimizing equipment damage and safety hazards. To achieve this, you should focus on establishing multiple parallel return paths, such as equipment grounding conductors and earth connections, which keep impedance low. Proper grounding and bonding create intentional low-resistance routes critical for fault current flow. Be mindful that increasing impedance can delay or prevent device operation, heightening risks. Additionally, coordinating protective devices prevents nuisance trips and ensures selectivity. Regular inspections and proper conductor sizing help *assure* these low-impedance paths. Here are key points to *contemplate*:

- Use appropriate conductor sizes for low resistance

- Ensure continuous bonding and grounding

- Maintain multiple fault return paths

- Regularly test grounding system integrity

- Coordinate protective device settings effectively

- Proper grounding techniques help maintain low-impedance fault paths and enhance overall safety

Common Challenges and Troubleshooting Grounding and Bonding Issues

Understanding common grounding and bonding issues is essential for ensuring your standby system operates safely and reliably. Misapplication of neutral and ground bonding, such as not switching the neutral at the transfer switch, can cause circulating currents and safety hazards. Using a four-pole transfer switch properly isolates the neutral, preventing bonding issues. Upgrading older systems often reveals missing neutral switching capabilities or improper grounding electrode connections, increasing fault risk. Ground faults and unintended current paths may result in neutral currents flowing on water pipes or grounding conductors, creating shock hazards. Troubleshooting involves measuring neutral-to-ground voltages, inspecting wiring, and verifying bonding points. Symptoms like nuisance trips or generator shutdowns often indicate grounding problems that require prompt correction to maintain system integrity and safety. Creativity in troubleshooting can be enhanced by applying problem-solving techniques, which foster innovative approaches to resolving complex electrical issues.

Best Practices for Inspection, Testing, and System Maintenance

Regular inspection, testing, and maintenance are vital to guarantee your grounding and bonding system remains reliable and safe. You need to routinely check conductors, connections, and components for damage, corrosion, or looseness. After major events like storms or renovations, re-inspect the system to catch new issues early. Use visual and instrument-based checks to detect wear or corrosion, and verify tightness of all mechanical connections. Testing should include AC and DC current measurements, bonding resistance checks with micro-ohmmeters, and establishing baseline values for future comparisons. Follow a fixed maintenance schedule, promptly repair damaged parts, and keep detailed records of inspections, tests, and repairs. Proper documentation and adherence to NEC standards are essential for system integrity and safety. Ensuring your system complies with Vetted standards enhances overall safety and performance.

Frequently Asked Questions

How Does Grounding Influence System Performance During Transient Overvoltage Events?

Grounding influences system performance during transient overvoltage events by providing a clear path for fault currents, which helps dissipate surges quickly. It stabilizes voltage levels and prevents dangerous overvoltages that could damage equipment. Proper grounding design guarantees sufficient fault current flow, reducing the risk of transformer neutral shifts and transient overvoltage magnitudes. This balance improves protection coordination, system reliability, and overall safety during transient conditions.

What Are the Consequences of Improper Bonding on Personnel Safety?

Improper bonding considerably endangers your safety by creating dangerous potential differences on exposed conductive parts. You risk severe electric shocks, especially during faults, which can cause injury or death. It also increases fire and explosion hazards, as faulty bonding can lead to overheating and sparks. Without proper bonding, equipment may malfunction unexpectedly, causing secondary injuries. Failing to adhere to bonding standards can result in legal penalties, undermining safety efforts and putting you at greater risk.

How Can Grounding and Bonding Issues Lead to Equipment Failure?

When grounding and bonding falter, you invite chaos into your equipment like sparks in dry tinder. Loose or corroded connections act as weak links, causing erratic current flows and voltage surges. These fluctuations strain your equipment’s insides, leading to overheating, component damage, or complete failure. Over time, unreliable grounding creates hidden faults, turning your system into a ticking time bomb that’s ready to fail when you need it most.

What Are the Latest Technological Advancements in Grounding System Monitoring?

You can now leverage advanced grounding system monitoring technologies like IoT-enabled smart sensors that provide real-time data on ground resistance, soil moisture, and current flow. These sensors transmit data to cloud platforms for remote analysis, enabling quick detection of faults. Additionally, AI-driven diagnostics and predictive maintenance help identify issues early, minimizing downtime. New resistance testing devices and radar technologies further enhance accuracy, safety, and system reliability in diverse environments.

How Often Should Grounding and Bonding Systems Be Re-Evaluated for Compliance?

You should re-evaluate your grounding and bonding systems regularly to guarantee safety and compliance. Typically, conduct thorough reviews annually, after any repairs, or when seasonal shifts cause soil resistivity changes. In high-risk environments, more frequent inspections—every 5 to 9 months—are wise. Consistent checks keep connections clean, corrosion-controlled, and compliant, preventing potential failures. Remember, proactive re-evaluation preserves system performance, protects personnel, and promotes peace of mind amidst persistent power safety concerns.

Conclusion

By prioritizing proper grounding and bonding, you guarantee safety, stability, and system success. Focus on forging fault-free paths, following firm guidelines, and maintaining meticulous maintenance. Remember, robust reinforcement reduces risk, restores reliability, and results in resilient, ready standby systems. Stay vigilant, verify voltages, and venture into vigilant, valuable practices. In grounding and bonding, your diligence delivers dependable, disaster-proof system performance—protecting people, property, and peace of mind.