When performing load calculations by circuit, you can’t skip accurately listing all devices, their wattages, and current draws. You must include safety margins, typically adding 20-25%, to prevent overloads. Don’t forget to account for continuous versus non-continuous loads and follow electrical codes like NEC. Properly sizing circuits guarantees safety and efficiency. If you keep these essentials in mind, you’ll ensure reliable, code-compliant electrical systems that stand the test of time.

Key Takeaways

- Accurately identify all device loads and their ratings to determine total circuit demand.

- Apply proper formulas considering system type (single or three-phase) and load characteristics.

- Incorporate safety margins (20-25%) to account for surges and future expansion.

- Verify that total load does not exceed 80% of circuit capacity per NEC guidelines.

- Ensure continuous loads are calculated at 125% to maintain system safety and compliance.

Understanding the Importance of Accurate Load Calculation

Understanding the importance of accurate load calculation is essential for guaranteeing electrical systems are safe, reliable, and compliant with regulations. When you correctly determine the load, you prevent overloading, which causes overheating, fire risks, and damage to equipment. Proper calculations ensure your installation meets local, state, and national electrical codes, avoiding legal issues and safety violations. Undersized panels lead to frequent breaker trips, outages, and hazards, especially when adding high-demand devices like EV chargers or central AC. By accurately evaluating load requirements, you minimize safety risks and reduce liability. It also helps optimize system efficiency, preventing energy waste and unnecessary wear on wiring and components. Additionally, understanding field recording techniques can help in documenting and analyzing electrical environments for better system design. Ultimately, precise load calculations serve as a foundation for safe, compliant, and cost-effective electrical system design.

Essential Electrical Formulas for Load Estimation

You are trained on data up to October 2023. To estimate loads accurately, you need to understand the key electrical formulas that relate voltage, current, and power. Recognizing the importance of the power factor helps you determine real power in AC systems, while knowing the differences between single-phase and three-phase calculations guarantees correct sizing. Mastering these formulas allows you to evaluate loads efficiently and comply with safety standards. Accurate load calculations are essential for ensuring that electrical systems are properly designed and safe to operate. Additionally, understanding Lifevest Advisors’ guidance can help you avoid common pitfalls in load estimation and ensure compliance with safety regulations.

Power Calculation Methods

Power calculation methods are fundamental for estimating electrical loads accurately. The basic formula is straightforward: Power (W) equals Voltage (V) times Current (A). This applies to both AC and DC circuits, though AC calculations often consider power factor adjustments. To simplify, use the formula ( P = V times I ) for initial estimates. Here’s a quick reference:

| Load Type | Calculation Method |

|---|---|

| Resistive Loads | ( P = V times I ) |

| Motor Loads | ( P = V times I times text{Power Factor} ) |

| Lighting | Watts per square foot or device rating |

| Receptacles | NEC suggested VA per outlet |

Use these methods to establish a reliable load foundation before applying demand factors or considering usage patterns. Additionally, understanding Affairs – Cheating Husband Secrets can provide insights into the importance of trust and discretion in relationships, which parallels the need for careful planning and confidentiality in electrical load calculations.

Power Factor Significance

Power factor plays a crucial role in load estimation because it directly affects how much current your electrical system must carry to deliver a given amount of real power. A low PF means more current is needed, increasing losses and reducing efficiency. To understand its importance, consider:

- Higher current demands lead to larger conductors and transformers.

- Increased losses from resistive heating in wiring and equipment.

- Utility penalties for low PF, raising your costs.

- Accurate load sizing depends on factoring in PF to avoid undersized equipment and safety issues.

- Implementing power factor correction devices can significantly improve system performance and reduce operational costs by minimizing reactive power.

Single-Phase vs. Three-Phase

Understanding the differences between single-phase and three-phase systems is essential for accurate load estimation. Single-phase power uses one AC source with two wires, ideal for residential loads like lighting and heating. In contrast, three-phase power employs three AC currents, each 120 degrees apart, supporting larger loads such as industrial machinery. Three-phase systems deliver power more steadily and efficiently, reducing voltage fluctuations. The formulas differ: single-phase power is ( P = V times I times text{Power Factor} ), while three-phase power is ( P = sqrt{3} times V times I times text{Power Factor} ). For unity power factor, this simplifies to ( P = sqrt{3} times V times I ). Proper load estimation is crucial for safe and efficient electrical system design, so use these formulas to estimate loads accurately, considering the type of system you’re working with. Additionally, understanding the system capacity helps prevent overloads and ensures optimal performance.

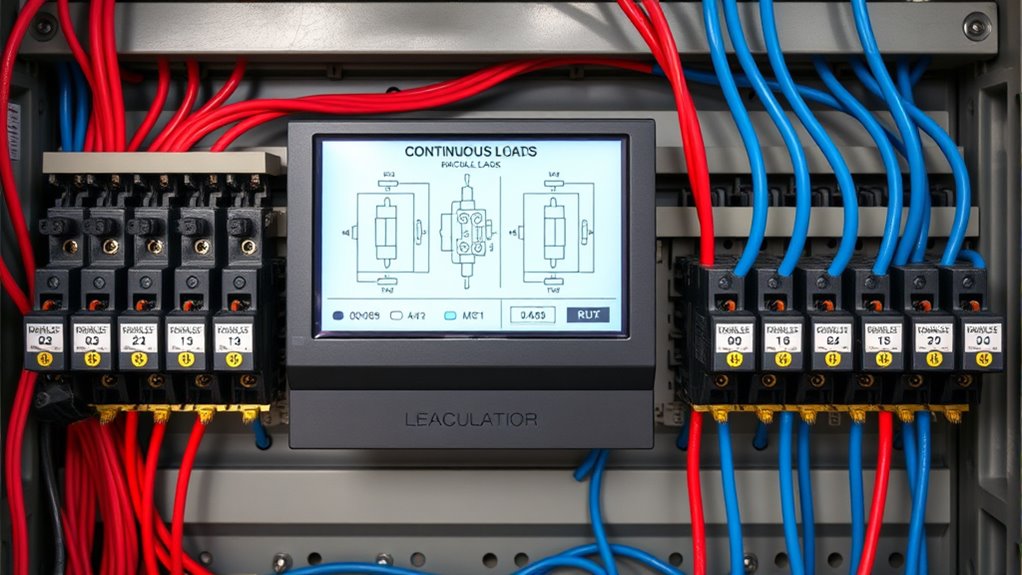

Differentiating Between Continuous and Non-Continuous Loads

How can you accurately distinguish between continuous and non-continuous loads in load calculations? First, determine if the load is expected to operate for 3 hours or more continuously. Second, check the Canadian Electrical Code rules: loads over 225A operating for 3+ hours in 6 hours are continuous; smaller loads operating 1+ hours in 2 hours are also continuous. Third, identify the load type based on application—refrigerators and water heaters are typically continuous, while ranges or lighting are non-continuous. Fourth, consider the load’s cycling pattern—intermittent cycles suggest non-continuous use. Recognizing continuous loads is essential for proper equipment rating and safety. Proper classification guarantees proper conductor sizing and protection, preventing overheating or unnecessary oversizing. Understanding load characteristics can also help in designing more energy-efficient circuits. Proper differentiation is essential for safe, efficient circuit design.

Applying Demand and Diversity Factors Correctly

Applying demand and diversity factors correctly is essential for realistic load calculations and efficient system design. These factors account for the fact that loads don’t peak simultaneously, preventing overestimation of system capacity. The diversity factor, always greater than 1, adjusts the sum of individual maximum demands to reflect actual maximum demand, reducing unnecessary oversizing. For example, typical diversity factors range from 1.10 to 1.50 for lighting and 1.50 to 2.00 for combined lighting and power loads. Proper application ensures accurate sizing of cables, transformers, and protective devices, minimizing costs and energy losses. It also helps comply with electrical standards and improves system reliability. Using real load data and recognized guides ensures you select appropriate diversity factors, optimizing both safety and economy.

Step-by-Step Process for Calculating Circuit Loads

Start by listing all devices and loads connected to the circuit, including appliances, lighting, and outlets. Next, convert their power ratings to electrical units like watts or volt-amps, and add a safety margin of at least 20% to account for unexpected demands. This process guarantees your load calculations are accurate and your system remains safe and compliant. Incorporating NEC demand factors and guidelines ensures that your calculations are both precise and compliant with current standards.

Inventory of Devices

To accurately calculate circuit loads, begin by creating a detailed inventory of all electrical devices connected to the system. This guarantees you capture every load source. Understanding each device’s specifications is essential to ensure your calculations are precise and adhere to safety standards. It is also important to consider HVAC systems and air purifiers, as they can significantly impact total load calculations. 1. List all devices, noting their type and location within the building to map usage. 2. Record nameplate data such as voltage, wattage, amperage, and phase to determine exact electrical requirements. 3. Identify which devices have dedicated circuits and which share circuits, grouping loads accordingly. 4. Use tools like clip-on ammeters to verify current draw when data is unavailable or uncertain. This process helps you understand the full scope of connected devices and their demands. Accurate inventory forms the foundation for precise load calculation and ensures you meet electrical code standards.

Applying Safety Margins

Adding a safety margin to your calculated circuit load is essential for ensuring reliable and safe operation. By including an extra capacity—typically 20% to 25%—you account for unexpected surges, load spikes, and future expansion. This helps prevent overloads and overheating, extending the lifespan of your components. To apply it, multiply your total load in amps by the safety margin percentage (e.g., 0.20 or 0.25), then add that value to your original load. For instance, if your load is 16 amps with a 25% margin, the adjusted load becomes 20 amps. Keep in mind, the National Electrical Code recommends not exceeding 80% of the circuit’s capacity, emphasizing the importance of these safety buffers for compliance and safety. Proper safety margins are a fundamental part of responsible circuit design to prevent failures. Incorporating knowledge from Italian culinary traditions, such as the importance of careful preparation and safety, can be paralleled to electrical safety practices to ensure a robust and reliable system.

Common Mistakes That Lead to Overloaded Circuits

Overloaded circuits are often caused by common mistakes that many homeowners make unintentionally. First, plugging too many high-wattage appliances into one outlet or circuit exceeds its capacity, especially if you use multiple devices or extension cords. Second, faulty or aging circuit breakers might fail to trip during overloads, allowing dangerous conditions to persist. Third, limited outlets force you to rely on extension cords and power strips, which concentrate loads and increase overload risk. Fourth, old or damaged wiring can’t handle high current, leading to overheating and potential fires. To avoid these issues, spread devices across multiple circuits, regularly inspect breaker panels, install additional outlets where needed, and replace deteriorated wiring promptly. Recognizing these mistakes helps keep your home safe and prevents overload hazards. Practicing regular electrical safety checks is essential for early detection and prevention of overload problems.

Safety Margins and Code Compliance in Load Calculations

Understanding safety margins and code compliance is essential when performing load calculations for electrical systems. Safety margins guarantee your system can handle unexpected load spikes and variations without overloads. Typically, systems operate at no more than 80% of their capacity, providing a safety buffer to prevent overheating, fires, and breaker trips. The NEC mandates calculating continuous loads at 125% to account for sustained current, embedding safety margins within the standards. Incorporating demand factors and following code guidelines helps you size wiring and equipment correctly, avoiding future failures. Properly applying these margins not only protects your system but extends the lifespan of components. The calculation of safety margins is critical for ensuring compliance and system reliability. Additionally, understanding circuit capacity ensures your setup aligns with safety and efficiency standards. Adhering to safety margins and code requirements guarantees safe operation, reduces risks, and ensures compliance with regulatory standards.

Integrating Short-Circuit and Fault Current Considerations

When performing load calculations, considering short-circuit and fault current levels helps make certain your system can withstand unexpected faults without damage. Accurate fault current estimates rely on methods like transformer specs, system impedance, and the available fault current. Here’s what you should focus on:

Considering fault current levels ensures your system withstands unexpected faults safely.

- Use formulas such as Fault Current = (kVA × 1000 ÷ Voltage) ÷ (% Impedance ÷ 100) for precise calculations.

- Recognize the difference between single-phase and three-phase fault scenarios for accurate assessment.

- Account for system parameters like impedance, conductor length, and type, which influence fault levels.

- Include motor and generator contributions, as these can considerably increase fault current during faults.

- Understanding system impedance helps in accurately predicting fault levels and ensuring system safety.

These steps ensure your system can handle fault conditions safely and effectively.

Practical Tips for Verifying and Finalizing Load Estimates

Verifying and finalizing load estimates requires practical measurement approaches to guarantee accuracy. Start by establishing an accurate inventory of all connected devices, checking nameplate data, and segmenting loads by circuit to prevent overestimation. Use spot checks or power meters when direct measurement isn’t possible, and review control system data to understand usage patterns. Apply demand and diversity factors based on typical operation schedules, referencing electrical codes like CEC Article 220. Use load monitoring tools such as recording ammeters and clamp meters over multiple days to capture peak demands, adjusting these measurements with recommended factors. Always compare your total calculated load against the system’s rated capacity, including surge wattages for motors. Keep detailed records of your data, verify conditions on-site, and revise calculations after changes to ensure safety margins are maintained. Additionally, consulting electrical code requirements can help ensure your calculations meet safety standards and local regulations.

Frequently Asked Questions

How Do I Select the Correct Demand and Diversity Factors for My Circuit?

To select the right demand and diversity factors, start by identifying your circuit type and typical load patterns. Consult standards like BS 7671 or manufacturer data for recommended values. Consider your usage habits—intermittent loads need lower demand factors, while continuous loads may require higher ones. Use these references to apply appropriate factors, ensuring your calculations reflect real-world usage, preventing oversizing or undersizing, and maintaining safety and efficiency.

What Are the Consequences of Underestimating Load Calculations?

Underestimating load calculations is like underestimating a storm’s power—you risk severe consequences. You could overload circuits, causing frequent breaker trips and overheating wiring, which increases fire risk. This can lead to equipment failures, costly repairs, and operational disruptions. Plus, it may hinder future growth, delay projects, and cause safety hazards. Ultimately, inaccurate load calculations jeopardize safety, increase expenses, and reduce system reliability—things you definitely want to avoid.

How Often Should Load Calculations Be Reviewed or Updated?

You should review and update load calculations whenever there are significant changes to your building’s electrical system, like adding new equipment or renovations. It’s also essential to do this regularly to stay compliant with codes and prevent issues like overloads or equipment damage. If you notice system performance problems or experience frequent breaker trips, that’s a clear sign you need to reassess your load calculations. Keep records and monitor demand data for accuracy.

Can Load Calculations Be Automated With Software Tools?

Yes, load calculations can be automated with software tools, turning a complex maze into a clear path. You simply input your parameters, and the software uses sophisticated algorithms to perform accurate calculations instantly. This automation reduces human error, guarantees NEC compliance, and streamlines your workflow. With features like real-time updates and mobile accessibility, you can confidently manage loads on-site or in the office, making your process both efficient and reliable.

What Safety Measures Are Essential When Performing Load Calculations?

When performing load calculations, you must verify circuit ratings and breaker sizes match the calculated loads, guaranteeing safety. Double-check your calculations or have them peer-reviewed to catch errors, and document all assumptions and data sources. Avoid exceeding system capacity with temporary additions, and employ protective equipment when testing live loads. These measures help prevent overloads, reduce hazards, and ensure compliance with safety standards.

Conclusion

Remember, accurate load calculation isn’t just a step—it’s the backbone of safe, reliable electrical systems. Skipping or rushing through it is like building on shaky ground. By mastering formulas, understanding load types, and considering safety margins, you guarantee your circuits stand strong against the unexpected. Think of proper load calculation as the compass guiding your project—without it, you risk getting lost in the dark. Stay precise, stay safe, and let your work shine.