To establish a safe extension‑cord strategy for portables, first assess your power needs by calculating the total wattage and selecting cords with appropriate gauges and lengths, ensuring they are rated for your devices. Regularly inspect cords for wear or damage, and avoid overloading by spreading high-demand tools across circuits. Properly install cords away from hazards, keep them organized, and ground them correctly. For more safety tips and detailed steps, continue exploring best practices for portable power management.

Key Takeaways

- Calculate total wattage and current draw of portable devices to select cords with appropriate gauge and capacity.

- Use extension cords with safety certifications, proper grounding, and suitable outdoor or indoor ratings as needed.

- Avoid daisy-chaining multiple cords; instead, use power strips or distribution boxes for extended reach safely.

- Regularly inspect cords for damage, wear, or overheating, and replace or repair damaged cords immediately.

- Position cords to prevent tripping, avoid pinched or wet areas, and keep cords off the floor when not in use.

Assessing Power Needs and Selecting the Appropriate Cords

To guarantee you choose the right extension cord, you first need to assess your power needs accurately. Start by totaling the wattage of all devices you’ll connect, which is usually on their labels or manuals. Divide this sum by your household voltage—typically 110-120V—to estimate the total current in amps. Round down this number to find the minimum wire gauge you need; most household devices require 12-gauge cords, while high-power tools demand 10-gauge or thicker. Remember, longer cords increase resistance, so for extended lengths, thicker wires are necessary to prevent voltage drops and overheating. Always consult electrical guidelines like the NEC and manufacturer recommendations to match cord gauge with your specific load and length requirements. Proper wire gauge selection is essential for safety and performance in your extension-cord strategy.

Ensuring Proper Inspection and Maintenance of Extension Cords

You need to regularly inspect your extension cords for signs of wear or damage, like cracks, fraying, or overheating. Catching issues early helps prevent electrical hazards and extends the cords’ lifespan. When repairs aren’t possible or damage is severe, it’s safest to dispose of the cords properly. Frequency of Inspection Regular visual checks help identify frays, cuts, or damage early and are recommended before each use. Incorporating safety standards from reputable sources ensures that your extension cords meet necessary electrical safety requirements. Additionally, choosing cords with proper insulation and grounding features can further reduce the risk of electrical issues.

Regular Visual Inspections

Regular visual inspections are essential for maintaining extension cord safety and preventing accidents. Before each use, check the cord for visible damage, such as cuts, frayed insulation, or scorch marks. Conduct thorough monthly inspections, focusing on plugs, connectors, and the entire length of the cord. Seasonal checks should address environmental damage from moisture, extreme temperatures, or UV exposure. Increase inspection frequency in high-risk environments like construction sites. Document inspection dates and findings to monitor cord condition over time. Look for bent prongs, loose parts, overheating signs, or internal damage. Confirm the cord’s rating matches its intended use. Proper inspections help identify potential hazards early, allowing for timely repairs or replacements, and keep your portable power setup safe and reliable. Regular inspections also help ensure the integrity of plugs and receptacles for safe operation. Additionally, understanding the contrast ratio of your equipment can enhance overall viewing safety and quality. Regularly reviewing cost variances can support better budgeting for maintenance and replacements, ensuring ongoing safety and performance. Paying attention to environmental factors can further extend the lifespan of your extension cords and prevent unnecessary failures. Incorporating visual inspection techniques can improve detection of subtle damages that might otherwise be overlooked.

Detecting Wear and Damage

Detecting wear and damage in extension cords requires careful inspection for signs of overheating, physical deterioration, and environmental effects. Look for discoloration, burn marks, melted insulation, or a burnt smell, which indicate thermal damage. Check for brittle or hardened insulation resulting from heat stress. During use, watch for sparks or smoke as immediate warning signs. Environmental factors like UV exposure, moisture, extreme temperatures, or contact with chemicals can weaken cords; inspect for cracks, cracks, or corrosion. Mechanical wear appears as bent, broken, or loose prongs, cracks in the housing, or damaged strain reliefs. Dirt, debris, and contaminants can hide damage and degrade insulation, making thorough cleaning part of proper maintenance techniques. Regular visual checks, disconnecting cords for detailed inspection, and using specialized testers help identify internal wire issues before hazards develop. Additionally, visual inspection methods are essential for early detection of potential hazards and ensuring the safe operation of extension cords, especially considering the role of AI in business to analyze such issues efficiently. Moreover, incorporating advanced diagnostic tools can further enhance safety by detecting hidden faults that are not visible to the naked eye.

Proper Repair and Disposal

Ensuring proper repair and disposal of extension cords is essential for maintaining safety and preventing accidents. Damaged cords should be rolled up, tagged clearly as “damaged” or “out of service,” and removed from use immediately. Proper labeling alerts staff and maintenance personnel, preventing unsafe cords from recirculating and reducing the risk of shocks or fires. When cords show visible defects like broken connectors or exposed wires, they must be taken out of service and disposed of safely—either by cutting the cord to disable it or transferring it to a recycling facility. Always document disposal or repairs to maintain safety records and comply with regulations. Regular inspections, proper repairs using approved parts, and adherence to OSHA standards ensure your cords stay safe and reliable. Incorporating load‑planning tools and safety checklists can further help identify potential issues early and prevent hazards before they occur. Additionally, understanding the financial impact of faulty equipment can motivate proactive maintenance and safety practices. Supermarket hours today can also influence the scheduling of maintenance activities, ensuring repairs are conducted during low-traffic periods to minimize disruption. Implementing proper training for personnel on cord inspection procedures further enhances safety and reduces the likelihood of overlooked damage.

Safe Installation and Placement of Extension Cords in Work Areas

Proper placement and routing of extension cords are essential to maintain a safe work environment. You should avoid running cords through doorways, under carpets, or across busy walkways to prevent trips and fires. Keep cords away from pinched areas like windows, doors, or sharp edges to avoid insulation damage. Do not hide cords inside ceilings or walls, which can cause overheating. Use cord protectors when crossing foot traffic zones to prevent damage. Routinely inspect cords for cuts, exposed wiring, or damage, repairing or discarding them promptly. Ensuring cords are properly rated for your specific use helps prevent electrical hazards and promotes safety. Additionally, selecting cords with safety certifications can further reduce risks of malfunction or failure. Incorporating organized cord management strategies can also help maintain a clutter-free and safer workspace. Regular training on extension cord safety can further enhance awareness and prevent accidents.

Managing Load Capacity and Preventing Overloads

You need to know your extension cord’s amp rating to avoid overloading it. Never connect too many devices or draw more current than the cord can handle, as this risks overheating. Using the proper length for your load helps prevent voltage drops and guarantees safe operation. Additionally, understanding load capacity is essential to prevent potential hazards associated with electrical overloads. Recognizing amp ratings and how they relate to your devices can help ensure safe usage. Recognizing angel numbers related to love can also offer spiritual reassurance during these safety considerations, especially if you’re navigating new or significant electrical setups.

Know Cord Amp Ratings

Knowing the amp rating of your extension cord is essential for managing load capacity and preventing overloads. The amp rating depends on the cord’s gauge, with thicker wires supporting higher currents. For example, a 16 AWG cord supports up to 13 amps, but only for shorter lengths. Longer cords need thicker gauges to handle the same load, like 12 AWG supporting 16–20 amps at 50 feet. To visualize, here’s a quick guide:

| Gauge | Length | Max Amps Supported |

|---|---|---|

| 16 AWG | 25–50 ft | 13 amps |

| 14 AWG | 50 ft | 15 amps |

| 12 AWG | 50 ft | 20 amps |

Matching your device’s current draw to the cord’s rating prevents overheating and hazards. Always check ratings before plugging in high-demand equipment.

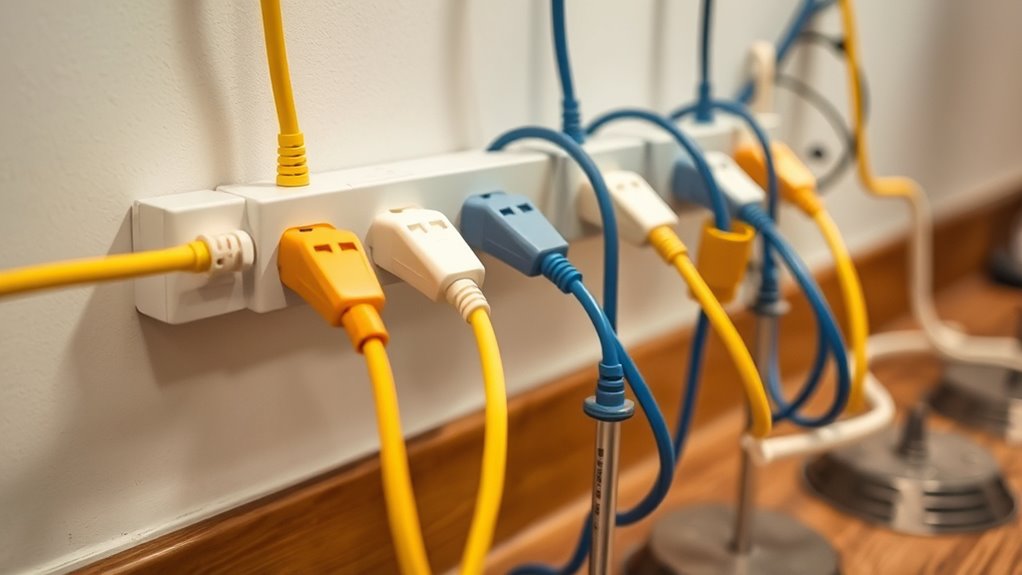

Avoid Overloading Circuits

Overloading a circuit can quickly lead to overheating, tripped breakers, or even fires. To prevent this, you must manage your load carefully. First, spread high-demand appliances—like air conditioners and dryers—across multiple circuits to avoid overloading a single one. Second, always calculate the total amperage of your devices and ensure it stays below 80% of the circuit’s capacity; surpassing this puts your safety at risk. Third, use power strips with surge protectors properly: plug each directly into a wall outlet, not into another strip, and avoid daisy-chaining. By following these steps, you keep your electrical system safe, reduce fire hazards, and ensure your portable setups stay reliable and secure.

Use Proper Extension Length

Using extension cords of appropriate length is essential to prevent voltage drops and overheating. OSHA recommends a maximum of 100 feet for temporary use, and longer cords increase resistance, leading to voltage loss and potential overheating. If you need more reach, use a power distribution box instead of a longer cord. Typically, cords come in 25, 50, or 100-foot lengths; exceeding these without proper wire gauge can cause excessive energy loss and risk equipment damage. For shorter distances, 16 AWG cords work for light loads, while 14 or 12 AWG cords are better for longer lengths and higher power demands. Always select a cord length that matches your load and avoid bundling or coiling, which can trap heat and create fire hazards. Proper length guarantees safe, efficient operation.

Implementing Safety Devices and Grounding Practices

Implementing safety devices and proper grounding practices is essential to prevent electrical hazards when using extension cords. You must use three-pronged cords with intact grounding wires, ensuring a safe path for fault current. Connect only three-prong plugs to grounded outlets—never modify cords or plugs. Regularly test and inspect grounding connections to maintain system integrity. To enhance safety, follow these steps:

- Use GFCI-protected cords in outdoor or damp environments to prevent shocks.

- Inspect cords daily for damaged insulation, exposed wiring, or faulty plugs—discard unsafe cords immediately.

- Choose heavy-duty, rated cords for high-demand equipment to avoid overheating and fire risks.

Handling and Storage Procedures for Portable Extension Cords

Proper handling and storage of portable extension cords help maintain their safety and longevity. Store cords in a dry, well-ventilated area away from extreme temperatures and direct sunlight to prevent damage. Use cabinets, drawers, or dedicated boxes to keep cords clean, protected from dust, pests, and moisture. Keep cords off the floor whenever possible to reduce tripping, crushing, or pest risks. When storing, coil cords into large, even loops to prevent kinks and internal wire damage, avoiding sharp bends. Use cord reels or straps to secure heavy-duty cords and prevent tangling. Inspect cords regularly for cracks, fraying, or loose plugs, setting aside damaged ones for repair or disposal. Label cords clearly by type and rating for quick identification, and organize them using hooks or hangers for easy access.

Monitoring and Responding to Potential Hazards During Use

Regularly inspecting extension cords during use is essential to identify potential hazards early. This proactive approach helps you catch issues before they cause harm. Focus on these key points:

- Look for visible damage like cracks, frays, or exposed wires that could lead to shocks or fires.

- Check for overheating signs—warm or hot cords mean danger, so unplug immediately.

- Monitor physical stresses such as pinching or kinking, especially where cords pass through doorways or under furniture, which can damage insulation.

Ensure plugs are fully inserted and no prongs are exposed. Keep cords out of walkways, securing them when crossing paths. Stay alert, and unplug damaged cords promptly to prevent accidents.

Frequently Asked Questions

How Often Should I Replace Damaged Extension Cords?

You should replace damaged extension cords immediately once you notice visible damage like fraying, cracks, or exposed wires. Regularly inspect cords before each use, especially in high-risk environments, and replace them if any damage is found. Industry experts recommend replacing cords every 3 to 5 years, but if damage occurs sooner, don’t delay—safety always comes first. Prompt replacement prevents electrical hazards and keeps your workspace safe.

Can Extension Cords Be Used Outdoors Safely?

Using extension cords outdoors is like walking a tightrope—you need the right equipment and caution. Yes, they can be safe if you choose cords explicitly rated for outdoor use, marked with a “W,” and follow safety practices. Inspect cords regularly for damage, avoid daisy chaining, and keep them away from water and damage-prone areas. Using GFCI outlets and proper grounding keeps you safe while enjoying the outdoors.

What Is the Maximum Length for Safe Extension Cord Use?

You should limit your extension cord length to 100 feet for safe use, especially with portable equipment. If you need to go beyond that, use a temporary power distribution box to split the power safely. Keep in mind, longer cords increase voltage drop and heat, which can cause damage or fire hazards. Always match the cord gauge to your device’s amperage and use GFCIs for added safety.

How Do I Identify if an Extension Cord Is Properly Grounded?

You can tell if an extension cord is properly grounded by inspecting its plug for an intact third prong and checking the cord for visible damage. Use a plug-in receptacle tester or multimeter to verify proper grounding and wiring. Regularly test with GFCI devices to detect faults. Always confirm the cord is rated correctly for your environment and certified by recognized labs, and avoid bypassing or removing grounding components.

Are There Specific Extension Cords for High-Power Tools?

Yes, there are specific extension cords designed for high-power tools. You should look for heavy-duty cords rated for at least 12 gauge wire, suitable for 15 to 20 amps, and labeled as outdoor or heavy-duty. These cords have thicker wiring to handle higher current loads safely, minimizing voltage drop and overheating risks. Always check the amperage rating and verify the cord meets or exceeds your tool’s power requirements for safe operation.

Conclusion

By following these steps, you’ll build a safety net that keeps your portable extension cords from turning into a tangled mess of hazards. Think of your strategy as a sturdy bridge—supporting your work without collapsing under pressure. Stay vigilant, regularly check your cords, and handle them with care. With this approach, you’ll guarantee a safe work environment where power flows smoothly, and risks stay grounded. Safety isn’t just a goal; it’s your best connection.