To test your generator under realistic load, start by inspecting it thoroughly and guaranteeing all safety measures are in place. Use a suitable load bank that matches your generator’s capacity—resistive, reactive, or a combination—to simulate real-world conditions. Gradually increase the load in steps, monitoring voltage, current, and temperature closely. Keep detailed records of each stage, then carefully reduce the load and allow the generator to cool. If you continue exploring, you’ll discover detailed steps to ensure safe, effective testing.

Key Takeaways

- Ensure the generator is fully inspected, fueled, cooled, and batteries are charged before starting load testing.

- Select a load bank compatible with the generator’s rated power, matching both resistive and reactive load types as needed.

- Gradually increase load in controlled steps, maintaining each level for 15-30 minutes to allow system stabilization.

- Continuously monitor electrical parameters, engine temperature, and vibrations, recording data at each load stage for analysis.

- Safely reduce load and allow the generator to cool down, disconnecting loads before shutdown for optimal performance assessment.

Understanding the Purpose of Load Testing

Why is load testing your generator essential? It verifies the engine can produce the necessary horsepower and rotational force needed for real power demands. By applying incremental loads, you simulate operational conditions from low to full capacity, ensuring the engine is ready to handle emergency situations reliably. Load testing exposes hidden engine issues that no-load tests might miss, like weaknesses in fuel or air systems. It also checks if critical components respond properly under stress. Additionally, it assesses the cooling system’s ability to manage heat during full load, preventing overheating. Load testing is vital for ensuring the generator’s overall performance and longevity. Stability of electrical output is confirmed by testing the alternator and voltage regulator under load, avoiding potential faults. Overall, load testing guarantees your generator will perform effectively and reliably when it’s most needed.

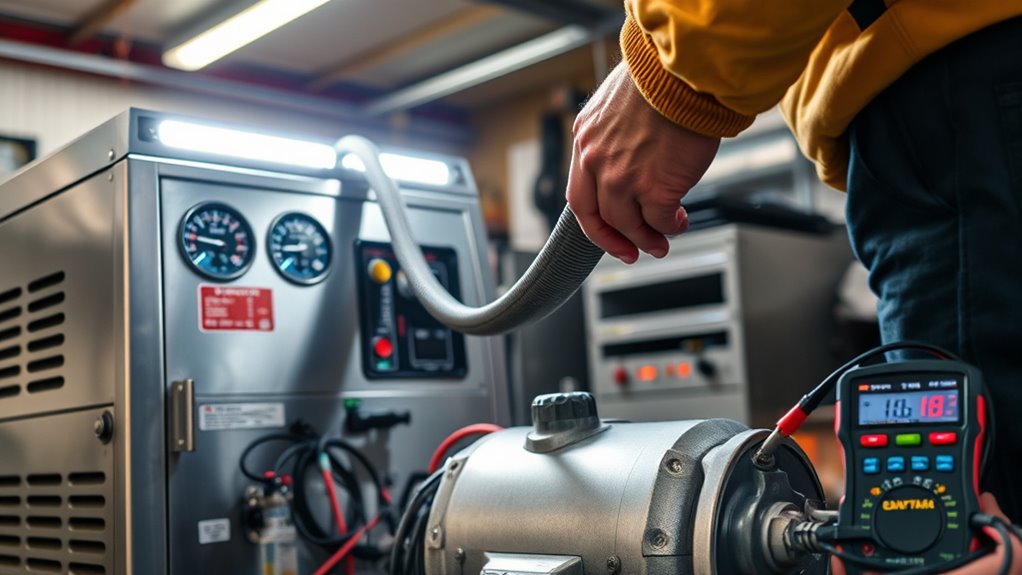

Preparing Your Generator for Testing

Before you begin load testing your generator, it’s essential to thoroughly prepare both the equipment and the testing environment. Start by verifying the generator is fully powered off, then conduct a visual inspection for damage, leaks, and secure electrical connections. Check fuel, oil, and coolant levels to ensure adequate supply for sustained operation. Confirm batteries and starting systems are charged and functional to prevent startup issues. Inspect automatic transfer switches (ATS), cleaning contacts as needed for reliable transfer during testing. Choose a well-ventilated, obstruction-free area to prevent heat or exhaust buildup. Ensure cooling fans for the generator and load bank are operational to avoid overheating. Keep safety equipment nearby, inform staff about the test, and prepare emergency shutdown procedures to respond quickly if needed. Proper preparation can help prevent unexpected failures and ensure a smooth testing process. Additionally, understanding air purifier maintenance can contribute to a healthier environment around your testing site, reducing airborne contaminants that could interfere with sensitive equipment or personnel safety. Regularly checking air filtration systems can further improve air quality and protect both the equipment and personnel during testing. Moreover, implementing automation in monitoring can enhance the accuracy of test results and provide real-time data for better decision-making.

Selecting the Appropriate Load Bank Equipment

Choosing the right load bank equipment means ensuring compatibility with your generator’s load type and capacity. You need to select a load bank that accurately matches your generator’s rated power and adheres to safety standards. Making the right choice helps you perform safe, effective tests that reflect real-world operating conditions. Proper selection also involves considering the specific application, whether for testing, maintenance, or backup power, to ensure the load bank provides the appropriate level of load for reliable results. Additionally, understanding the load capacity of your generator helps prevent overload and potential damage during testing. When selecting load bank equipment, considering the performance standards can ensure compliance with industry regulations and safety protocols. Being aware of the nutritional value of juices can be beneficial when selecting consumables or supplements to support generator maintenance crews during extended testing sessions. To ensure safe operation, always verify that the load bank’s design features meet industry safety and performance standards.

Load Type Compatibility

Selecting the right load bank equipment is essential to accurately simulate your generator’s operational conditions. Resistive load banks are ideal for testing full kW capacity, as they convert electrical energy into heat and replicate heat-producing devices. Reactive load banks, on the other hand, simulate motor-driven equipment with inductive or capacitive components, challenging your generator’s voltage regulation and performance under typical power factors. For facilities with mixed loads, combined resistive/reactive load banks provide a thorough testing solution. Electronic load banks offer programmable, precise control for specialized tests. Ensuring the load bank’s voltage and current ratings match your generator’s specifications is vital for safe, realistic testing. Proper load type compatibility guarantees your generator performs reliably under real-world conditions.

Power Rating Accuracy

Accurate power rating alignment between your load bank and generator is key to effective testing. The load bank must match or slightly exceed the generator’s maximum rated output to confirm full capacity testing. For example, a 630 kVA generator needs a load bank with at least 630 kVA capacity. Resistive load banks support testing at 100% of the nameplate kW but only about 80% of kVA due to power factor limits. Inductive banks or combined units can simulate 100% kVA, matching the generator’s actual load profile. It is crucial to select equipment that reflects the generator’s power factor and type—AC or DC—so all components are tested under realistic conditions. Proper sizing ensures your test verifies generator reliability without under- or overloading the equipment. Additionally, understanding power factor considerations helps in choosing the right load bank setup for accurate testing. Using the correct type of load bank also ensures that testing conditions are representative of real-world operation, providing more reliable and meaningful results. Recognizing load bank efficiency can further optimize testing procedures and equipment lifespan.

Safety and Compliance

Ensuring safety and compliance starts with verifying that your load bank equipment meets the generator’s maximum output ratings and is compatible with its voltage and phase specifications. Choose a load bank rated to handle at least the generator’s peak output to prevent overloads. Confirm compatibility with your generator’s voltage and phase to ensure accurate testing and safety. Prioritize load banks with safety features like thermal protection and remote monitoring. Proper installation is key—install in ventilated areas, verify cable ampacity, and match phases to prevent faults. Use the following table to guide your selection:

| Criterion | Importance | Action |

|---|---|---|

| Capacity | Prevent overloads | Select load bank ≥ generator max output |

| Compatibility | Ensure accurate testing | Match voltage and phase specifications |

| Safety Features | Protect equipment and personnel | Prioritize models with safety protections |

| Environmental Conditions | Maintain hardware longevity | Install in ventilated, dry areas |

| Monitoring & Controls | Facilitate safe operation | Choose load banks with remote monitoring options |

Additionally, understanding the contrast ratio of your load bank can help ensure it provides the appropriate level of load for comprehensive testing. It is also important to be aware of potential regulatory compliance requirements to ensure your testing process adheres to safety standards and legal guidelines. Incorporating a detailed understanding of load bank specifications can further optimize your testing procedures and ensure compliance with industry standards. Furthermore, selecting a load bank with a suitable power factor correction can improve testing accuracy and equipment longevity.

Gradually Applying the Load and Monitoring Parameters

When applying load to a generator, it’s essential to do so gradually to prevent sudden stress that could cause damage. You should start by increasing the load in controlled increments, typically from 10-30%, depending on the generator size and testing protocol. To guarantee safety and accuracy, follow these steps:

- Use calibrated switches on load banks for precise kW increments.

- Maintain each load step for a stabilization period, usually 15-30 minutes.

- Monitor electrical parameters like voltage, current, and frequency continuously.

- Observe mechanical and thermal indicators, including engine temperature and vibrations, ensuring they stay within acceptable limits.

- Recognize that monitoring science helps ensure accurate data collection and system safety during testing. Employing effective document management practices can also assist in recording and analyzing test results efficiently. Additionally, understanding load application techniques can optimize the testing process and reduce potential risks. Incorporating proper safety protocols is crucial for protecting personnel and equipment during load testing.

This approach helps thermal and mechanical systems stabilize, minimizing the risk of damage and providing reliable data on generator performance.

Incorporating Different Load Types for Comprehensive Testing

To get a full picture of your generator’s performance, you need to incorporate different load types during testing. Resistive loads simulate steady power demands, while reactive loads challenge the alternator’s stability and voltage regulation. Using a variety of loads helps identify potential issues and guarantees your generator can handle real-world operating conditions effectively. Additionally, understanding load management techniques ensures you can optimize your generator’s performance under various demands. Incorporating power quality considerations during testing can further help maintain stable voltage and prevent damage to connected equipment. Properly simulating dynamic loads is also essential for assessing how your generator responds to fluctuating power requirements. Considering load variability enables a more comprehensive evaluation of generator reliability under different scenarios.

Resistive Vs Reactive Loads

Understanding the differences between resistive and reactive loads is essential for thorough generator testing, as each type affects the generator’s performance in distinct ways. Resistive loads convert electrical energy directly into heat, providing a steady, predictable demand that tests real power capacity and thermal limits. Reactive loads, such as motors or transformers, induce magnetic fields and cause phase shifts, testing the generator’s ability to handle reactive power and voltage regulation.

- Resistive loads evaluate the generator’s thermal and fuel systems under full load.

- Reactive loads assess voltage stability and reactive power handling.

- Combining both types simulates real-world conditions for exhaustive testing.

- Using mixed loads ensures your generator performs reliably across diverse operational scenarios.

Benefits of Diverse Testing

Incorporating different load types into generator testing creates a more realistic assessment of its performance, as real-world electrical demands are rarely uniform. By using diverse load profiles, you can see how your generator responds to sudden fluctuations, continuous operation, and transient conditions. Different load types—inductive, capacitive, and non-linear—stress various components uniquely, helping identify weaknesses that might not appear under steady loads. This approach also reveals how the engine, alternator, and control systems work together during complex scenarios, including startup and shutdown cycles. Testing with varied loads uncovers potential issues like voltage instability, harmonic distortion, or thermal hotspots early. Overall, diverse testing improves reliability, informs maintenance, and guarantees your generator performs at its best during actual power demands.

Observing and Recording Operational Data During the Test

During load testing, it is vital to systematically observe and record key operational data to evaluate generator performance. Accurate data collection helps identify potential issues and verifies capacity. Here are four essential aspects to focus on:

Systematic data recording during load testing ensures accurate performance evaluation and reliable capacity verification.

- Log electrical parameters like frequency, voltage, amperage on all phases, and power factor during each load step.

- Monitor engine and generator health indicators, including oil pressure, coolant temperature, and exhaust temperature.

- Record DC battery voltage to guarantee starting system integrity throughout the test.

- Track environmental conditions, such as ambient temperature, and measure total power output (kW) and load percentage to assess efficiency and capacity.

Consistent, precise recording ensures thorough performance analysis and reliable results.

Safely Disengaging the Load and Allowing Cool-Down

Before shutting down the generator, you should disconnect all electrical loads to prevent equipment damage and reduce stress on the system. Gradually reduce the load to avoid sudden power surges and mechanical stress. Restore control devices, like excitation varistors, to their normal settings for system stability. Decrease the voltage to its minimum before switching off the output. Follow the manufacturer’s shutdown sequence, including turning off power and closing fuel valves. After load removal, let the generator run unloaded for several minutes to cool down. Keep the area well-ventilated, monitor gauges for temperature and vibration, and avoid covering the generator. Turn off the generator only after it’s cooled, ensuring fuel is shut off and the system is stable. Never refuel hot equipment to prevent fire hazards during cool-down.

Analyzing Test Results and Identifying Potential Issues

Analyzing your generator load test results is essential for identifying potential issues that could affect performance and reliability. Carefully review the data to spot abnormal patterns or deviations from manufacturer specs.

- Check engine parameters like temperature, oil pressure, and RPM for stability and consistency across load steps.

- Assess electrical performance by examining voltage output, current balance, and frequency regulation for signs of dips or surges.

- Look for harmonic distortion and power factor deviations, which can indicate power quality issues.

- Compare recorded data against baseline readings to identify irregularities such as voltage drops, transient responses, or control system malfunctions.

Maintaining Your Generator for Optimal Performance

Regular maintenance is essential to keep your generator running at peak performance. Start with regular visual and physical inspections—look for corrosion, leaks, or damage on the exterior, and check seals, joints, and connections for wear or looseness. Clear debris from air intakes and radiator fins to prevent overheating. Examine wiring, battery terminals, belts, and hoses, replacing any worn or cracked parts. Change engine oil after the first 30 hours, then every 100 hours or annually, and replace filters regularly to protect the engine. Keep coolant levels topped off and clean the radiator. Test the battery and electrical connections, ensuring tightness and no corrosion. Run the generator under load monthly to lubricate parts and identify issues early, adjusting your maintenance schedule based on performance data.

Frequently Asked Questions

How Often Should Load Testing Be Performed on My Generator?

You should perform load testing on your generator based on its use and importance. For non-mission critical units, monthly tests at 30-50% load are recommended, while annual tests at higher loads are typical for less critical applications. Critical systems like hospitals need more frequent, stringent testing, often weekly or quarterly. Always follow manufacturer guidelines and industry standards to guarantee your generator remains dependable during outages.

What Safety Precautions Are Essential During Load Bank Testing?

During load bank testing, you must wear PPE like gloves, goggles, and hearing protection to prevent injuries. Confirm the test area is clean, dry, and hazards are removed. Verify all equipment is in good condition, electrical connections are secure, and the emergency stop is functional. Match load settings carefully, avoid exceeding capacity, and monitor the generator closely. Only qualified personnel should perform tests, and all safety procedures must be strictly followed.

Can Load Testing Damage My Generator if Not Done Properly?

You might worry that load testing could damage your generator, but improper procedures cause most issues. If you overload the generator, skip warming up, or ramp up loads too quickly, you risk overheating, mechanical stress, or electrical faults. Poor cooling, faulty load banks, or neglecting safety measures can also lead to damage. Proper planning, gradual load application, and monitoring help prevent these problems and protect your generator’s lifespan.

How Do I Interpret Abnormal Readings During a Load Test?

When you see abnormal readings during a load test, look for voltage and frequency fluctuations, which signal system instability or component issues. Notice sudden drops or inconsistent patterns—these may point to loose wiring, mechanical faults, or fuel problems. Elevated temperatures or unusual noises indicate overheating or mechanical wear. Also, watch for protective relay trips, which suggest electrical faults. Analyzing these signs helps you identify underlying issues and prevents potential equipment damage.

What Maintenance Is Needed After Completing a Load Bank Test?

After completing a load bank test, you should inspect and clean your generator. Check for any visual damage or abnormalities, and clean spark plugs, fuel injectors, and air filters. Verify fluid levels, including oil and coolant, and guarantee the cooling system operates properly. Test and adjust engine controls, record test data, and schedule preventive maintenance like oil or filter changes. This keeps your generator reliable and ready for future use.

Conclusion

Sure, testing your generator under realistic load might seem like a hassle, but neglecting it could leave you stranded when you need power most. Ironically, the very effort to guarantee reliability can reveal hidden issues, saving you from costly repairs later. So, embrace the process—you might just find that the true test isn’t the load, but your preparedness. After all, a well-tested generator is the best insurance against unexpected failures.