To winterize your backup power system, start by inspecting and cleaning all components, including belts, electrical connections, and fuel lines. Switch to winter-grade oil and add fuel stabilizer to prevent gelling. Protect your batteries with insulation and warmers, and perform operational tests to guarantee reliability. Store your generator properly and keep it free of debris. If you want detailed strategies to keep your system ready during cold weather, keep exploring further instructions.

Key Takeaways

- Conduct thorough inspection and cleaning of generator components, including fuel system, electrical wiring, and exterior surfaces.

- Drain fuel tanks and carburetors, add fuel stabilizer, and switch to winter-grade oil for optimal cold-weather performance.

- Store batteries separately in a cool, dry place, and use warmers and insulation to prevent freezing and capacity loss.

- Perform operational tests before winter, ensuring reliable startup and functioning, and check all cold-weather accessories are properly installed.

- Position generators outdoors at least 20 feet away, ensure proper exhaust venting, and never operate indoors to maintain safety.

Conduct a Thorough Inspection and Cleaning

To guarantee your backup power system operates reliably during winter, start with a thorough inspection and cleaning. Examine the generator casing for cracks or structural damage, which can worsen over time. Look for signs of corrosion on metal parts, as this can weaken components. Inspect belts and pulleys for wear and ensure they have proper tension to prevent slippage. Check all electrical wiring for loose, frayed, or corroded connections to maintain safety. Clean debris from air intake ports to improve airflow and engine efficiency. Additionally, clean or replace fuel filters for smooth fuel flow. Regular maintenance, including filter replacement, helps your system stay reliable when you need it most during winter. Remember to also review your at‑home maintenance routines to ensure ongoing system performance.

Adjust Oil and Fuel Systems for Cold Temperatures

To prepare your backup power system for cold weather, start by switching to winter-grade oil that flows better in low temperatures and reduces engine strain. It’s also vital to add fuel stabilizer to prevent gelling and drain any old fuel to avoid blockages. These steps help ensure reliable operation when temperatures drop. Regularly inspecting your system’s fuel lines and components can prevent unexpected failures during winter months. Proper maintenance and timely checks are crucial for ensuring your system performs optimally during winter conditions, especially considering the importance of filter replacement for continuous efficiency. Additionally, implementing preventive maintenance routines can further safeguard your system against harsh winter conditions and mitigate cybersecurity threats that could impact your system’s operation.

Use Winter-Grade Oil

Cold temperatures cause oil to become thicker and less fluid, which can impair engine performance and increase wear during startup. Thicker oil increases friction, strains engine parts, and may trigger low oil pressure sensors, preventing your generator from starting. To guarantee proper lubrication, switch to winter-grade oil suited for cold conditions. Use SAE 5W-30 synthetic oil below 20°F, or SAE 10W-30 for moderate cold. Consider this table for oil choices: oil viscosity and ensure your fuel system is properly adjusted for cold weather to prevent fuel gelling and maintain optimal operation. Additionally, understanding engine performance in cold temperatures can help you make better maintenance decisions. Recognizing how cold weather effects impact engine components can further improve your winterization process.

Add Fuel Stabilizer

Adding fuel stabilizer is a crucial step in preparing your generator for winter. It prevents fuel degradation by inhibiting oxidation and stopping gum and varnish buildup inside the fuel system. Stabilizer keeps fuel fresh for up to a year, reducing the risk of stale fuel that can clog carburetors, filters, or injectors. Use a stabilizer formulated for cold temperatures to ensure proper fuel flow in freezing conditions. Fill your tank before adding the stabilizer to minimize air space and oxidation. After pouring in the stabilizer, run your engine for 5 to 10 minutes to circulate the treated fuel thoroughly. Follow the manufacturer’s instructions for proper dosage, and avoid waiting until the tank is nearly empty to treat the fuel. Proper maintenance of your fuel system can also help prevent fuel system issues during winter months, especially considering how fuel stability impacts overall generator performance. Regularly inspecting and replacing old fuel components can further enhance fuel system reliability, which is essential as climate change impacts weather conditions and can lead to unexpected cold snaps that challenge your generator’s operation.

Drain Old Fuel

Old fuel left in your generator can degrade over time, especially during winter months. To prevent issues, drain the fuel completely and run the engine dry. This eliminates residual fuel that can oxidize, forming varnish and deposits harmful to engine parts. Draining also stops gelling or wax formation, which is especially important for diesel fuel in cold weather. If you’re storing your generator long-term or the fuel has been sitting for over 30 days, emptying the tank ensures system integrity. Avoid leaving old fuel that could clog fuel lines, filters, or the carburetor, causing poor performance or stalling. Properly draining your fuel system reduces moisture buildup, lowering corrosion risks and ensuring your generator is ready to operate reliably when you need it most. Additionally, understanding the artistic significance of butter can help you appreciate the cultural value of preserving traditional craftsmanship and materials used in various art forms. Regular maintenance, including fuel system care, is crucial for optimal winter performance and longevity of your backup power system. Performing a seasonal inspection can help identify potential issues before they become major problems during winter, especially given the importance of integrating technology in family activities for modern preparedness.

Maintain and Protect Your Battery System

To keep your backup power system dependable through winter, you need to maintain and protect your batteries. Regularly inspect and clean terminals, guarantee your batteries are fully charged, and perform capacity tests to spot any issues early. Using insulation and warmers can also help prevent cold-related capacity loss and extend battery life. Additionally, selecting the right battery type and features can enhance your system’s winter performance. Be sure to monitor your battery’s health regularly to catch potential problems before they impact your power supply.

Inspect and Clean Terminals

Regularly inspecting and cleaning your battery terminals is essential to guarantee your backup power system remains reliable. Start by visually checking for corrosion, such as white or greenish deposits, and look for any cracks, damage, or looseness in the terminal clamps. Ascertain all connections are tight to prevent resistance and heat buildup. Look for electrolyte leaks or buildup near the terminals, which can cause corrosion. When cleaning, use a baking soda and water mixture carefully with a brush, avoiding splashes on wiring or the casing. Rinse thoroughly and dry completely. Afterward, apply a thin layer of petroleum jelly or dielectric grease to inhibit future corrosion. Avoid harsh abrasives, and always handle the battery safely during inspections to maintain ideal performance.

Charge and Test Battery

Maintaining proper charge levels and testing your battery regularly guarantees your backup power system stays reliable during winter. Fully charge batteries before cold weather arrives to maximize capacity and reduce freezing risks. Use a trickle charger to keep batteries topped off during inactivity, and avoid letting charge drop below critical levels, which can damage capacity. Regular testing helps identify performance issues early. Perform load tests to ensure your battery can support critical circuits. Use this table as a guide:

| Action | When to Do It | Tips |

|---|---|---|

| Fully charge batteries | Before winter | Use indoor or temperature-controlled environments |

| Test capacity and voltage | Monthly or pre-storm preparations | Use system apps or manual checks |

| Perform load tests | Quarterly or during high demand | Verify batteries support essential circuits |

Stay proactive to keep your system ready all winter.

Use Insulation and Warmers

Keeping your backup power system protected during winter involves using both effective insulation and warmers to prevent freezing and guarantee reliable operation. High-performance foam pipe insulation offers a strong thermal barrier with low heat transfer, while flexible insulated pipe sleeves conform to irregular shapes, minimizing heat loss. Thermal blanket heaters combine insulation and active heat, keeping equipment above freezing. Foam pipe wrap tape protects exposed pipes and valves from freezing. Insulation bags designed for batteries and enclosures trap heat and block cold air. Wrap insulation tightly around the battery case, terminals, pipes, and cables for maximum protection. Leave ventilation ports unblocked to prevent moisture buildup. Regularly inspect and adjust insulation to ensure it remains effective. Incorporate warmers like heat trace cables or blanket heaters to maintain consistent temperatures.

Install Essential Cold-Weather Accessories

Installing essential cold-weather accessories is vital to guarantee your backup power system operates reliably during freezing temperatures. These accessories protect critical components, ensuring your generator starts and runs smoothly in winter.

Ensuring reliable backup power in winter requires installing essential cold-weather accessories.

- Battery warmers and heaters keep batteries above freezing, reducing strain and improving cold starts.

- Fuel system protectors, like fuel regulator heaters and line insulation, prevent fuel gelling and line freeze-ups.

- Engine and oil heaters maintain proper viscosity, reducing wear and startup delays.

- Breather tube heaters and insulated covers protect against moisture buildup and wind chill, maintaining optimal engine performance.

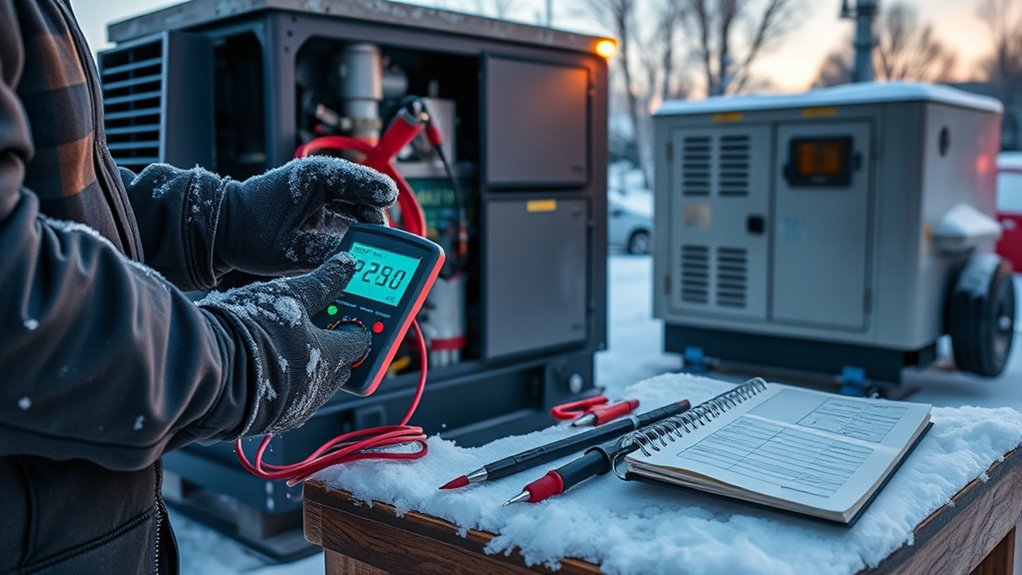

Perform Operational Testing and Continuous Monitoring

Before winter arrives, it’s essential to perform thorough operational testing on your backup power system to guarantee it functions reliably in cold conditions. Run your system for at least 30 minutes, watching for irregularities like sputtering, unusual noises, vibrations, or temperature changes. If you have dual-fuel or alternate fuel options, test these to confirm seamless switching under cold weather. Run emergency generators before severe weather forecasts to verify startup reliability. Continuously inspect critical components—check wiring, hoses, filters, and battery health, replacing weak batteries as needed. Monitor heat trace lines and fluid levels, ensuring proper lubrication and freeze protection. Use remote systems to track performance, set alerts for faults, and log all tests to improve winterization strategies and maintain readiness throughout the season.

Prepare and Properly Store Your Generator During Off-Use Periods

Proper storage of your generator during off-use periods is essential to make certain it remains reliable when you need it most. Follow these steps to ensure it’s ready for future use:

- Choose a dry, well-ventilated indoor space like a garage or shed, or protect outdoor storage with a weatherproof cover.

- Drain fuel tanks and carburetors if storing longer than 30 days, or add a fuel stabilizer for shorter periods.

- Remove the battery, store it separately in a cool, dry place, and keep it charged with a maintainer.

- Clean the exterior, apply rust inhibitors, and inspect electrical connections for corrosion, ensuring everything is dry and protected.

These steps help prevent moisture, rust, and fuel degradation, keeping your generator ready for the next power need.

Implement Safety Measures for Winter Operation

Ensuring your safety during winter operation involves more than just preparing your generator; it requires implementing key safety measures to protect your household and property. Always keep emergency supplies like flashlights, batteries, first aid kits, bottled water, and blankets accessible. Include a portable phone charger to stay connected during outages. Position generators outdoors, at least 20 feet from your home, and never run them inside or in garages to prevent carbon monoxide poisoning. Direct exhaust away from living areas and avoid refueling when hot. Use safe heating sources like fireplaces or wood stoves with proper ventilation, and regularly check their condition. Maintain sufficient fuel supplies, use winter-rated fuel, and perform periodic tests to ensure reliable operation. Educate your household about safety procedures and keep emergency contacts handy.

Schedule Regular Maintenance and Professional Check-Ups

Scheduling regular maintenance and professional check-ups is essential to keep your backup power system reliable during winter. Proper upkeep prevents unexpected failures when you need it most. To stay ahead, consider these key steps:

- Schedule annual professional service to inspect the engine, fuel system, battery, and electrical parts before winter hits.

- Increase service frequency if your generator runs often or faces harsh conditions.

- Document all maintenance to track service dates, parts replaced, and warranty info.

- Perform battery checks, including cleaning terminals, testing voltage, and replacing weak batteries to ensure reliable starts.

Following these steps helps maintain peak performance and avoids costly breakdowns during outages. Regular maintenance keeps your backup power system ready to serve when winter storms strike.

Frequently Asked Questions

How Often Should I Perform Winter-Specific Generator Maintenance?

You should perform winter-specific generator maintenance at least every 6 months or every 400 hours of use, whichever comes first. Schedule professional inspections in late September or October, just before winter begins. Also, run the generator monthly for 20-30 minutes, check fuel levels, and clear snow or debris to guarantee peak operation. Adjust frequency if you’re in harsh environments or using the generator heavily during winter.

What Are the Signs of a Failing Battery in Cold Weather?

When your battery starts failing in cold weather, you’ll notice slow engine cranks or sluggish starter sounds. You might hear clicking noises when trying to start your vehicle, and your headlights could dim or flicker. If the vehicle refuses to start even after multiple attempts, or electrical accessories malfunction, these are signs your battery is weak. Keep an eye out for these symptoms to prevent unexpected breakdowns during winter.

Can I Use Regular Motor Oil During Winter?

You can’t confidently use regular motor oil during winter because it thickens in cold temperatures, causing sluggish starts and stressing your system. Thicker oil increases engine wear, worsens fuel efficiency, and risks shutdowns. Instead, switch to winter-grade oil, which flows freely in freezing weather, lubricates smoothly, and keeps your generator going strong. Protect your power supply by prioritizing proper winter oil to prevent problems and promote peak performance.

How Do I Prevent Ice Buildup in Exhaust Outlets?

To prevent ice buildup in exhaust outlets, you should install snow hoods with downward-facing ducts to block snow entry, and place deflectors made of durable materials like Plexiglas to keep snow out without restricting airflow. Position pipes at a slight downward angle, and locate vents in sheltered areas away from snowdrifts. Regularly clear snow and ice around the outlets, and consider heated ducts and motorized louvers to maintain proper temperature and airflow during winter.

What Safety Precautions Are Essential When Operating in Freezing Temperatures?

When operating in freezing temperatures, you need to treat safety like a shield around you. Always position your generator outdoors or in a well-ventilated area to prevent carbon monoxide buildup—think of it as a gust of fresh air for safety. Keep pathways clear of snow and ice, wear insulated clothing to fend off the cold, and follow manufacturer protocols. Stay vigilant, so hazards don’t sneak up like winter’s silent threat.

Conclusion

Think of winterizing your backup power system as tending a delicate garden in frost. With careful inspection, protective measures, and ongoing care, you guarantee it’s ready to bloom when needed most. Like a gardener shielding fragile blooms from winter’s chill, your vigilance keeps your system resilient through the cold. When spring arrives, you’ll reap the rewards of your diligent preparation—trusting your backup power to stand strong, just as a well-tended garden flourishes despite the frost.