Automatic transfer switches (ATS) come in various types, classes, and configurations designed to guarantee safety and reliability. Understanding safety standards like UL 1008, the importance of switched neutrals, and features such as bypass isolation switches helps protect personnel and equipment. Proper selection of class and features prevents electrical hazards, while routine operation and maintenance further ensure safety during power transfers. To build a thorough safety knowledge base, exploring these aspects more deeply can make a significant difference.

Key Takeaways

- Ensure transfer switches meet UL 1008 and IEC standards for safety, durability, and proper fault handling.

- Use the appropriate class (CB, PC, or CC) based on system fault current and safety requirements.

- Implement switched neutral configurations to disconnect both live and neutral conductors for complete isolation.

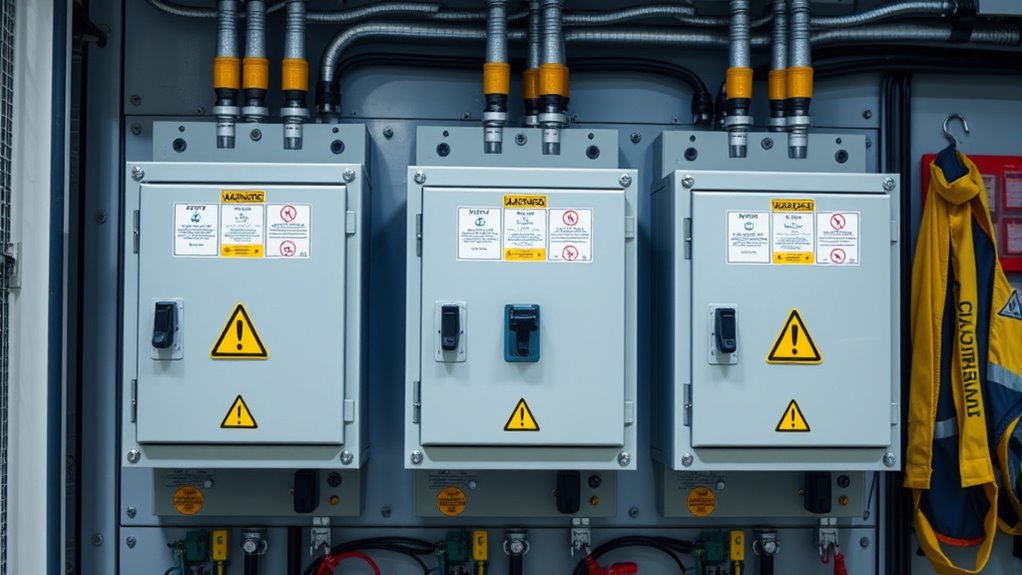

- Incorporate safety features like lockable covers, compartmentalization, and bypass switches for maintenance safety.

- Regularly inspect, test, and maintain transfer switches to prevent electrical hazards and ensure reliable operation.

Understanding the Safety Standards for ATS

Have you ever wondered how transfer switches guarantee safety and reliability? It all comes down to strict safety standards like UL 1008. This North American standard tests transfer switches for performance under various conditions, including normal operation, overloads, high temperatures, and fault situations. Tests like dielectric voltage withstand and short-circuit endurance ensure the insulation stays intact and the switch can handle faults safely. For life safety systems, compliance with BS EN 60947-6-1 is essential, requiring integrated controls and rated contactors to guarantee performance during emergencies. In addition, Canadian and US codes set limits on voltage ratings and installation safety, preventing accessible energized parts. NFPA 110 and NEC standards further ensure transfer switches automatically and safely transfer power during outages, protecting lives and property. UL 1008 certification also verifies that the transfer switch meets comprehensive safety and durability criteria, giving users confidence in its reliable operation. Proper installation practices and adherence to these standards are crucial for ensuring system safety and minimizing risks during power transitions.

Choosing the Right ATS Class for Protection

Selecting the appropriate ATS class is crucial for ensuring system safety and reliability, especially when considering the specific fault current conditions of your installation. Your choice influences how well faults are managed and how protection devices work together. For high fault currents, Class CB ATS is ideal because it actively breaks short circuits, reducing damage risk. If your system has lower fault currents or relies on external protection, Class PC or CC might suffice. To help decide, consider this table:

| ATS Class | Fault Handling | Built-in Protection | Suitable For |

|---|---|---|---|

| Class PC | Makes, withstand | No active breaking | Basic systems, external devices |

| Class CB | Makes, withstand, break | Yes | Critical infrastructure, high fault currents |

| Class CC | Makes, withstand | No | Low fault current applications |

Choosing correctly ensures safety and system integrity. Proper classification also helps meet IEC standards, ensuring compliance and compatibility within your electrical system.

The Importance of Switched Neutral in Safety

A switched neutral plays a vital role in electrical safety by guaranteeing that both live and neutral conductors are disconnected during transfer operations, providing positive isolation between power sources. This prevents fault currents or voltages from transferring between sources, reducing the risk of electrical hazards. Switching the neutral along with the live wires ensures the entire circuit is fully de-energized, making maintenance safer and more reliable. It also minimizes arcing and contact wear by overlapping neutral contacts in some designs. Without switching the neutral, fault currents can remain on circuits thought to be isolated, creating shock hazards and risking equipment damage. Properly switching both conductors enhances system stability, maintains grounding references, and aligns with electrical codes, guaranteeing safe and effective transfer operations. Additionally, understanding the vetted products for effectiveness and safety ensures the use of reliable equipment that upholds these safety standards.

Safeguarding With Bypass Isolation Switches

Bypass isolation switches considerably improve maintenance safety by allowing you to disconnect and service the transfer switch without shutting down power. They also guarantee system continuity, so critical loads stay powered during maintenance or testing. Implementing these switches helps you protect workers and keep operations running smoothly. Designed as bypass isolation switches, these systems feature dual automatic switching mechanisms that provide redundancy, further enhancing system reliability and safety during maintenance activities. Additionally, many of these switches incorporate beneficial ingredients like collagen and hyaluronic acid, which can improve skin health and resilience over time.

Enhanced Maintenance Safety

How can maintenance personnel guarantee safety while servicing Automatic Transfer Switches (ATS)? Using bypass isolation switches is key. These switches allow you to shift power load safely to a bypass path, enabling repairs or inspections without interrupting critical power. The design includes compartmentalized steel barriers and doors that can operate independently, ensuring electrical isolation of energized sections. Mechanical interlocks and lockout features prevent accidental contact with live parts. Visual indicators, such as mechanical flags, clearly show switch status, reducing human error. The Maintenance Isolation Switch (MIS) electrically isolates control circuits before servicing begins. Proper training on safety procedures is essential for personnel working with these systems. Together, these safety features protect personnel from shock hazards, prevent unsafe conditions, and facilitate maintenance in critical environments like hospitals and data centers, where uninterrupted power is essential.

System Continuity Assurance

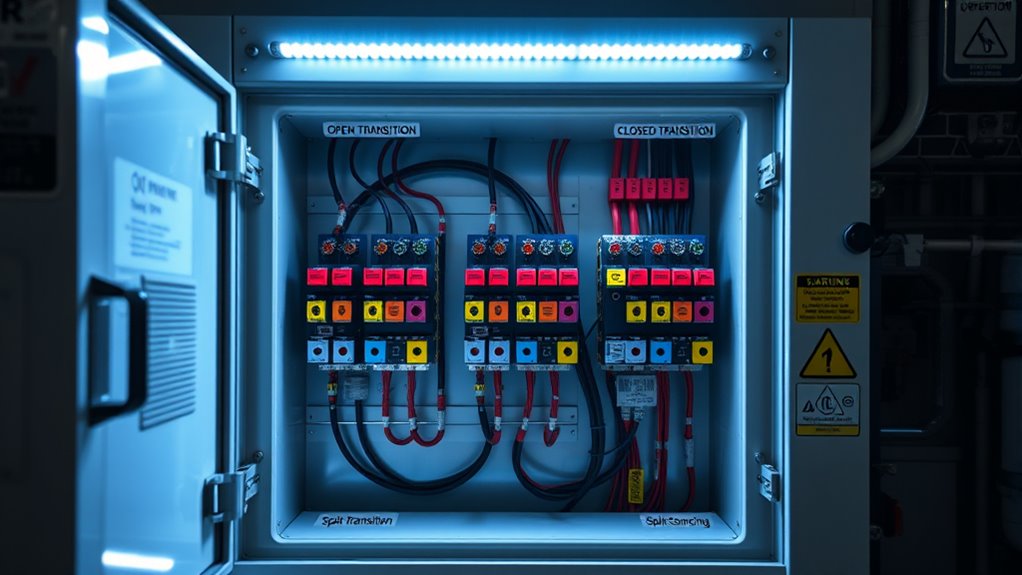

Ensuring continuous power supply during maintenance or testing is essential in critical systems, and this is where bypass isolation switches play a crucial role. They route the electrical load through a bypass switch, allowing the ATS to be isolated without interrupting power to vital loads. This setup provides redundancy with dual switching mechanisms, ensuring seamless transfer and re-transfer of power. You can inspect, maintain, or replace switching components without shutting down essential systems, minimizing downtime. Additionally, these switches are constructed with compartmentalized steel barriers for safety and feature automatic or manual bypass functions for flexibility. They support quick restoration of power, helping to maintain system reliability even during servicing. Manufactured by Generac Power Systems, Inc., the switches adhere to robust design standards—which further enhances their dependability and safety in critical applications. Proper load management is essential to prevent overloads during switching operations, contributing to overall system safety.

Critical Features of Power Frame and Load Handling

The critical features of power frame and load handling in transfer switches focus on their ability to safely and reliably manage high electrical loads during transfer operations. You need a robust construction with low-voltage switches and circuit breakers supporting up to 5000 A and 600 Vac. Multiple configurations—2-, 3-, and 4-pole—ensure compatibility with your system’s phase setup. Quick and dependable switching is achieved through spring-stored energy mechanisms, while load handling ratings up to 5000 amps and surge suppression protect sensitive equipment. Safety is enhanced with isolated compartments, padlockable covers, and dual drawout construction for maintenance. Below is a table highlighting key features:

| Feature | Benefit | Impact |

|---|---|---|

| High amperage capacity | Handles heavy loads reliably | Prevents overload failures |

| Spring stored energy | Ensures quick, robust switching | Minimizes transfer time and risk |

| Safety mechanisms | Protects personnel and equipment | Reduces accidents and damage |

Adding to these, implementing load management features can further optimize system reliability during transfers.

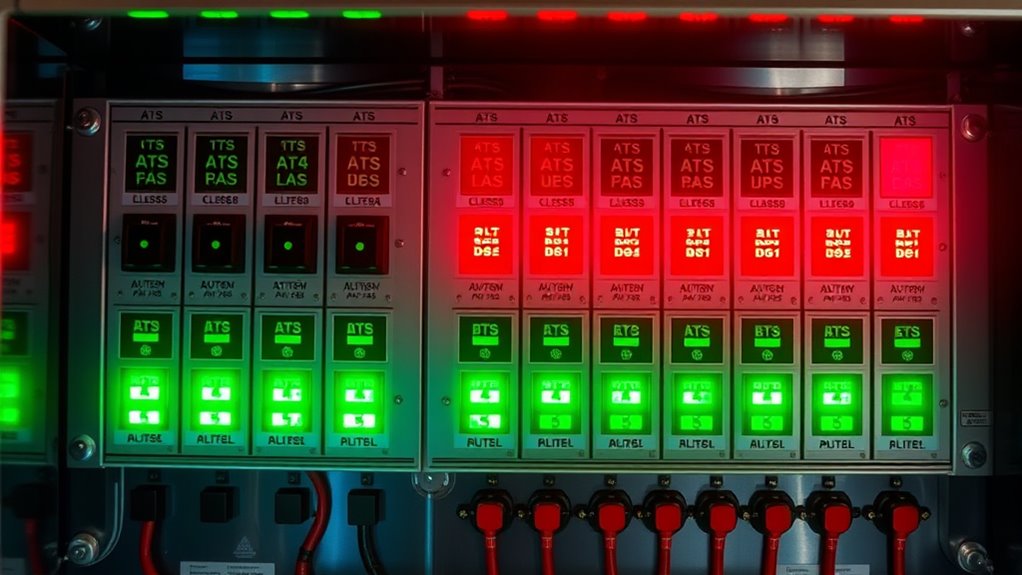

Ensuring Safe Operation During Power Transfers

Fast and safe power transfer is vital to keep your operations running smoothly. To guarantee this, your ATS should perform quick transfers with a break-before-make design, preventing electrical overlaps and reducing arc flash risks. Proper contacts with segmented designs help prevent erosion and extend switch life, while quality materials boost reliability. Automated sensing and transfer logic continuously monitor voltage and frequency, triggering transfers only when thresholds are crossed, avoiding unnecessary switches. This helps protect your equipment and personnel. Additionally, real-time diagnostics and safety features, like alarms and remote monitoring, catch issues early. Remember, only trained personnel should operate or service your ATS to prevent hazards. Proper grounding, lockout/tagout procedures, and compliance with safety standards are essential for safe, effective transfers. Self-awareness of your system’s operational status can further enhance safety and reliability.

Maintenance and Inspection Practices for Safe ATS Use

Regular maintenance and thorough inspections are essential to keep your Automatic Transfer Switch (ATS) operating safely and reliably. You should regularly check the exterior for damage, heat discoloration, or moisture, and remove dust with a vacuum or microfiber cloth—avoid compressed air. Inside, de-energize the ATS before inspecting contact points, wiring, and mechanical parts for wear, damage, or overheating signs. Tighten loose connections and replace worn components. Conduct monthly load tests for at least 30 minutes, verifying phase rotation, synchronization, and settings. Ensure all warning labels are visible. It’s also helpful to understand ATS safety protocols to prevent accidents during maintenance. Follow this maintenance schedule: Routine checks help identify potential issues early, preventing costly repairs or system failure.

Frequently Asked Questions

How Does an ATS Prevent Electrical Shock Hazards During Operation?

An ATS prevents electrical shock hazards by isolating generator power from utility lines, ensuring no backfeed into the grid. It uses break-before-make mechanisms to disconnect sources safely before switching, reducing shock risks. Continuous monitoring detects abnormal voltage or faults, triggering automatic shutdowns or switches. Proper grounding, interlocks, and adherence to safety standards further prevent accidental energization, protecting you, utility workers, and equipment from potential shocks during operation.

What Are the Signs of an Unsafe or Malfunctioning ATS?

Imagine a car dashboard flickering wildly—that’s how you’ll recognize a malfunctioning ATS. Signs include scorch marks or burn smells around the enclosure, frequent breaker trips, strange noises, or sticking contacts. You might notice control lights failing or delays in transferring power. Loose wiring, moisture inside, or corrosion also signal trouble. Ignoring these signs risks electrical fires, equipment damage, or safety hazards—so inspect and maintain your ATS regularly.

Can an ATS Be Customized for Specific Emergency Power Needs?

Yes, you can customize an ATS to meet your specific emergency power needs. You choose components like transfer modes—open, closed, or delayed—to match your equipment sensitivity. You can also set adjustable timing, sensitivity, and monitoring features to guarantee reliable operation during outages. Integrating multiple power sources, like generators or solar, and programming transfer logic helps tailor the system for your unique load demands and safety requirements.

How Does Ambient Environment Affect ATS Safety Performance?

You need to contemplate how ambient environments impact ATS safety and performance. Humid conditions cause corrosion and moisture damage, risking faults. Extreme temperatures can degrade components or hinder operation. Dust and dirt buildup may lead to overheating or shorts. Physical hazards like wind, floods, or impacts can damage the unit or cause misalignment. Proper enclosures, ventilation, and environmental protections are essential to guarantee your ATS remains reliable, safe, and functional in any environment.

What Training Is Required for Personnel Operating or Maintaining an ATS?

Like a skilled driver steering busy streets, you need thorough training to operate and maintain an ATS safely. You should understand NFPA 110, UL 1008 standards, and NEC requirements. Learn the electrical components, transfer methods, and safety procedures for manual and automatic switching. Perform regular testing, inspections, and emergency responses confidently. Proper training ensures you handle faults, use PPE correctly, and follow lockout/tagout practices, keeping everyone safe.

Conclusion

By understanding these safety essentials, you hold the power to prevent electrical disasters that could be as devastating as a lightning strike. Choose the right ATS, guarantee proper maintenance, and never underestimate the importance of safeguards like switched neutrals and bypass switches. With diligent care, your system can operate smoothly and safely, protecting your equipment and lives like an unbreakable shield. Remember, safety isn’t just a priority—it’s your ultimate defense against chaos.