To guarantee your transfer switch works reliably, place it near your main electrical panel in a dry, ventilated spot that’s easily accessible and safe from moisture or corrosion. Secure it in a lockable enclosure to prevent tampering, and verify it matches your generator’s capacity. Proper wiring, load management, and compliance with local codes are essential. Keeping the switch well-maintained and tested ensures longevity and safety—discover the best practices that truly make a difference.

Key Takeaways

- Select a dry, well-ventilated site near the main panel, avoiding moisture and hazards.

- Ensure the transfer switch is within 60-75 feet of the generator, using proper wiring for longer distances.

- Use lockable enclosures and tamper-evident seals to secure the switch from unauthorized access.

- Properly size the switch to match generator amperage and ensure compatibility with existing electrical systems.

- Regularly inspect, test, and maintain the transfer switch to ensure safe operation and compliance with codes.

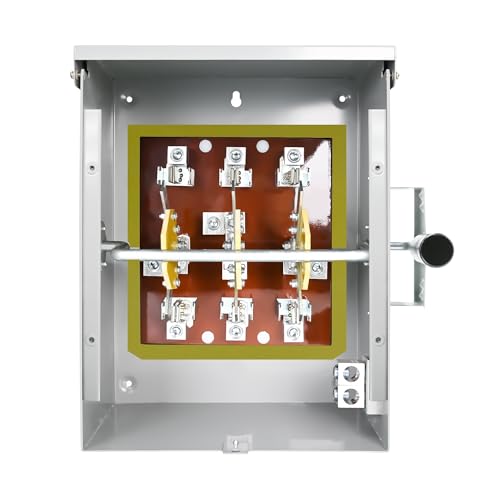

100A Generator Transfer Switch, 24000W Heavy Duty Double Throw Safety Design, 120/240V Transfer Switch for Installation Outdoor and Indoor,Stronger Stability,Enlarged NEMA 3R Enclosure for Easy Wiring

【100 Amp Generator Transfer Switch】This transfer switch is perfect for shifting power from the utility grid to an…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Selecting the Optimal Location Near Your Main Electrical Panel

Choosing the right location for your transfer switch is essential, especially near your main electrical panel. Placing it close minimizes wiring length, reducing voltage drops and electrical losses. Shorter wires also lower the risk of faults and overheating, enhancing safety. An adjacent position makes it easier to connect to existing circuits and complies with electrical codes, which often specify installation near the service entrance. This proximity simplifies troubleshooting, maintenance, and future upgrades for electricians. Ensure the site allows safe access and enough space for wiring and ventilation. Confirm the placement supports proper isolation from utility power and generator input, preventing backfeed hazards. Proper placement also helps ensure compliance with local electrical codes and safety standards. Additionally, considering proper grounding techniques during installation can prevent electrical hazards and improve overall system performance. By selecting a location that balances accessibility, safety, and code compliance, you set the foundation for a reliable and efficient transfer switch setup.

BESYL 50-Amp Generator Inlet Box NEMA 3R Plug, SS2-50P Power RV Indoor/Outdoor Waterproof Transfer Switch Inlet Box Plug, 3 Prong, 125/250 Volts, Up to 12,500 Watts, ETL Listed

Knockouts Notice: No Knockouts, No drilling required. Only need to unscrew the nut inside of the BESYL 50…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

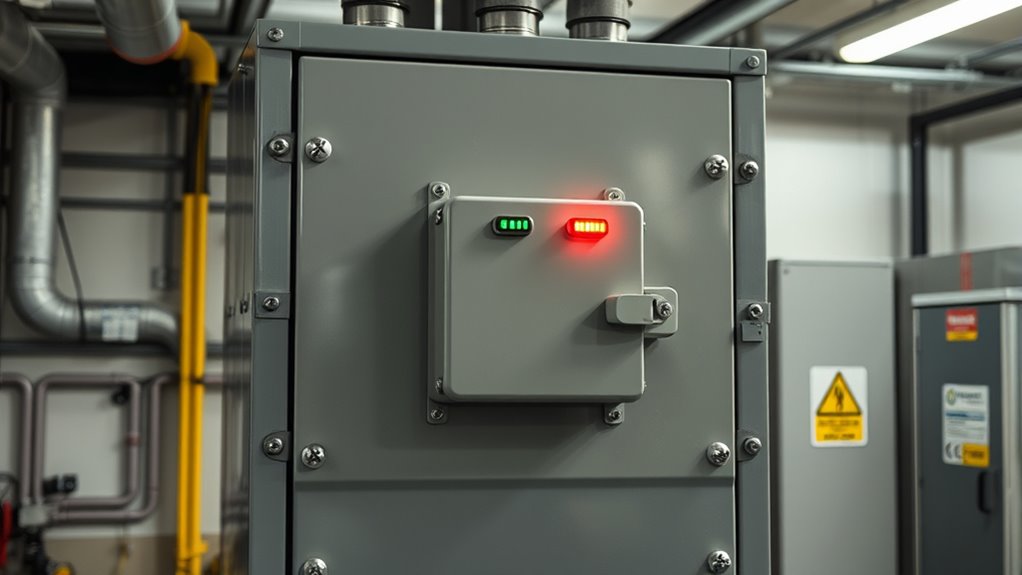

Ensuring Environmental Suitability and Accessibility

Selecting a suitable location for your transfer switch involves considering environmental conditions and ease of access. Make certain the enclosure meets UL 1008 safety standards and has the appropriate NEMA rating for your environment—NEMA 1 indoors or NEMA 3R for outdoor use. It must withstand ambient temperatures, humidity, and contaminants typical of the site. Confirm proper ventilation or cooling to prevent overheating. The installation site should be free from flooding, excessive moisture, and corrosive atmospheres. Accessibility is vital; position the switch where maintenance and testing can be performed safely and comfortably. Leave enough space around the unit for removal or replacement, and incorporate adequate lighting and signage. Lockable enclosures enhance security, while weatherproof seals protect against environmental hazards. Continuous learning about best practices ensures reliable and safe transfer switch placement.

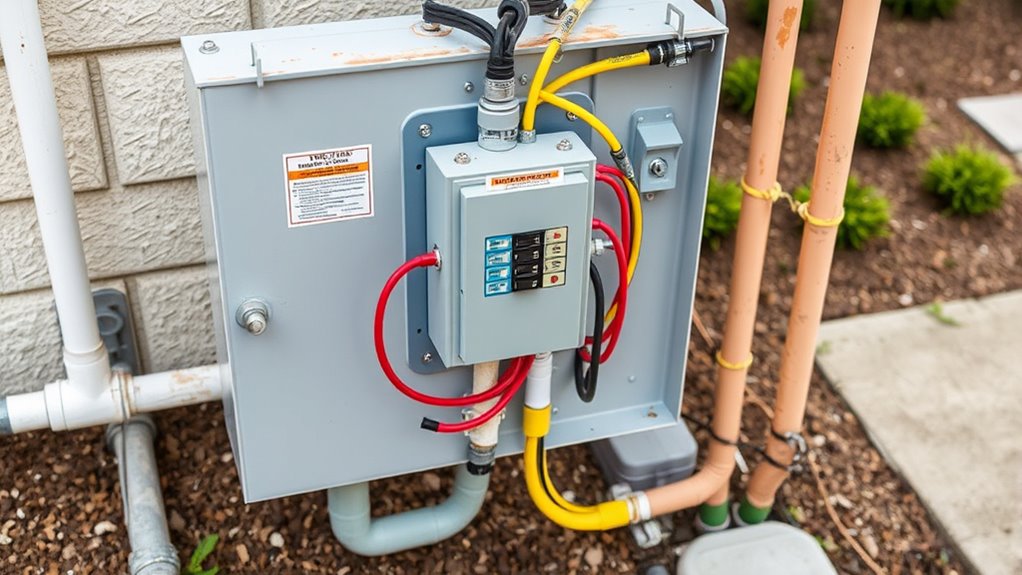

ZHWYBXS 200-Amp Generator Transfer Switch, 3 Pole 120/240V Manual Transfer Switch for Home Generator, 48,000 W Heavy Duty Double-Throw Power for Outdoor&Indoor, Meeting NEMA 3R Standards

Sturdy Durable: The 200A manual generator transfer switch enclosure is constructed from heavy-duty galvanized steel, offering both robustness…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

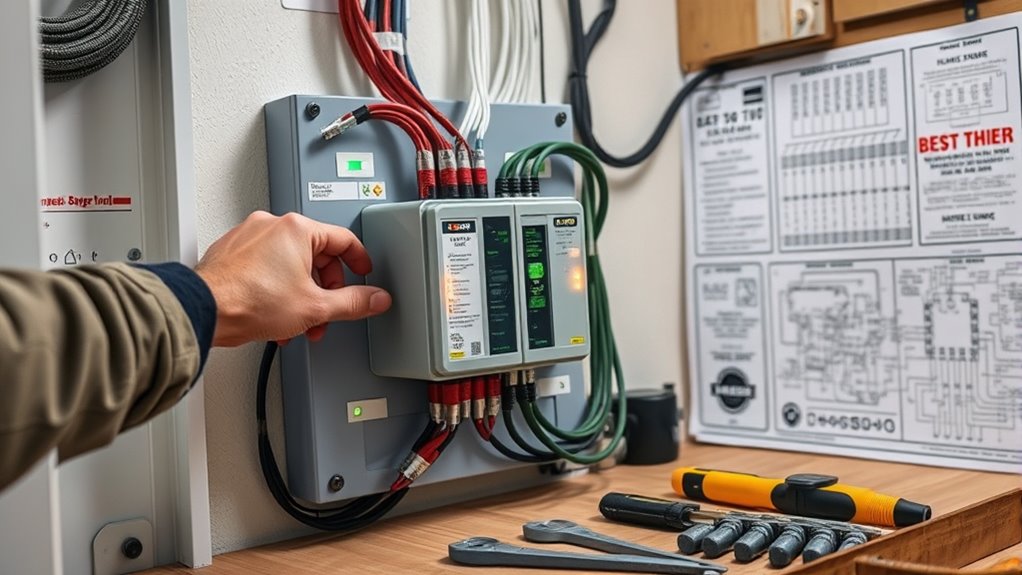

Proper Wiring Techniques and Load Management Strategies

Proper wiring techniques are essential for guaranteeing safe and reliable transfer switch operation. You need to follow specific practices to prevent hazards and ensure smooth functionality. A thorough understanding of load management strategies can also optimize system performance and reduce the risk of overloads. 1. Use permanent wiring methods, like cable or conduit, from the generator inlet to the transfer switch—flexible cords aren’t compliant with safety codes. 2. Match wire and cable sizes to the load and manufacturer guidelines, avoiding overheating or electrical failures. 3. Label all wiring components clearly before installation to prevent mistakes and maintain clarity during troubleshooting. Ensure all connections are tight and well-insulated, reducing the risk of arcing or short circuits. Follow manufacturer instructions closely to keep your setup compatible and up to code. Proper wiring and load management keep your system safe, efficient, and reliable.

Transfer Switch 50 Amp, 6 Circuit 120/240V Pre-Wired Automatic Transfer Switch Kit for Home Generator, Meeting NEMA 3R Standards for Outdoor and Indoor

Automatic Transfer Switching System: The 50-amp generator transfer switch kit features intelligent control mode, ensuring effortless and worry-free…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Complying With Local Electrical Codes and Regulations

To guarantee your transfer switch installation meets all safety standards, you need to understand the permitting and inspection process required by your local authorities. Compliance with electrical codes isn’t optional; it safeguards your property and ensures legal approval. Make sure you follow all regulations carefully to avoid delays and potential hazards. Interception of utility power before the main breaker is generally considered illegal, so proper placement and protection of transfer switches are essential for safety and compliance. Additionally, understanding the local water park regulations can help prevent violations related to outdoor electrical installations.

Permitting and Inspection Processes

Understanding the permitting and inspection processes is essential to guarantee your transfer switch installation complies with local electrical codes and regulations. To do this effectively, you need to:

- Submit complete permit documents, including electrical riser diagrams, single line diagrams, load calculations, and equipment specifications.

- Ensure all mechanical permits related to generators and transfer switches are submitted alongside electrical permits.

- Prepare for inspections by verifying proper bonding, grounding, disconnect means, and placement according to NEC standards, and confirm warning signs are installed.

- Review local requirements periodically because regulations may change or vary between jurisdictions, impacting your compliance process. Additionally, understanding the inspection procedures can help you prepare for possible revisions or additional documentation requests.

Following these steps helps you avoid delays and ensures your installation meets safety standards. Utility approval might also be required before connection, so stay in contact with local authorities throughout the process.

Code Compliance and Safety

Ensuring your transfer switch installation meets local electrical codes and regulations is a vital step in safeguarding your system’s safety and reliability. The NEC mandates transfer switches for all standby systems (Article 702.6) and requires them to be automatic, electrically operated, and listed for emergency use (Article 701). Emergency loads need a dedicated transfer switch, separate from optional loads, and all equipment must be approved by the authority having jurisdiction. Proper signage at service entrances, clear labeling, and fault protection are essential for compliance. Use appropriately sized circuit breakers, avoid upstream utility voltage interception, and ensure generator-neutral bonding. Proper interaction between generator and switch, including GFCI protection for frame-mounted receptacles, is crucial for safety and code adherence.

| Requirement | Specifics |

|---|---|

| Mandatory Transfer Switches | NEC Articles 702.6 & 701 |

| Emergency Load Transfer | Separate transfer switch for emergency loads |

| Signage and Labeling | Clear, visible signage and circuit labels |

| Wiring & Overcurrent Protection | Proper sizing, fault protection, and wiring methods |

| Generator Compatibility & Bonding | Load capacity, neutral bonding, GFCI requirements |

Determining the Correct Transfer Switch Size and Compatibility

Selecting the right transfer switch size is essential for safe and reliable power transfer during outages. To do this effectively, verify the switch’s amperage matches your generator’s maximum output. Consider these key points:

- Match the transfer switch’s amperage to the generator’s maximum amperage output, especially if using a pre-existing tap box. Ensuring proper sizing helps prevent overloads and equipment failure.

- Calculate your load requirements by listing essential appliances and systems to determine the total amperage, not just the generator’s rating. Knowing your power needs is crucial for selecting the appropriate switch.

- Verify compatibility with your electrical panel’s main breaker size—using a switch rated for your panel ensures seamless operation and code compliance.

- Remember that size refers to amperage, not physical dimensions, so choosing the correct amperage is crucial for safety and performance.

Avoid undersizing to prevent overheating or failure, and oversizing to avoid unnecessary costs. Consult a licensed electrician to confirm proper sizing and compatibility for your system.

Preparing for a Safe and Efficient Installation Workflow

Preparing for a safe and efficient transfer switch installation begins with careful site selection and thorough planning. Choose a dry, well-ventilated area near the main electrical panel for easy access and maintenance. Ensure the location allows proper clearance for airflow and meets local electrical codes. Keep the transfer switch within 60-75 feet of the generator to minimize voltage drop; use appropriately sized wiring for longer distances to prevent power loss or overheating. Maintain at least 5 feet between the generator and any building openings to reduce carbon monoxide risks and fire hazards. Clear the site of obstructions and moisture to prevent electrical damage during installation. Follow safety protocols, such as disconnecting power, wearing protective gear, and using insulated tools, to guarantee a safe, smooth workflow. Additionally, consider the security of your electrical setup to prevent tampering or theft of crucial components.

Securing the Transfer Switch to Prevent Unauthorized Access

Securing the transfer switch against unauthorized access is essential for maintaining system integrity and safety. Proper physical security minimizes risks of tampering and theft. Here are key measures to implement:

- Use robust, lockable enclosures or panels to prevent unauthorized physical access.

- Enclose switches in dedicated, locked rooms or cages accessible only to authorized personnel.

- Apply tamper-evident seals on access points to detect unauthorized interference quickly.

- Incorporate strong authentication mechanisms such as controlled access systems like keycards or biometrics for enhanced accountability. Additionally, consider controlled access systems like keycards or biometrics for enhanced accountability. Position the transfer switch in visible, monitored locations to deter tampering and facilitate rapid detection of suspicious activity. Regularly review security protocols and ensure all access points are properly secured. Implementing security best practices helps create a strong barrier against unauthorized intrusion, safeguarding your transfer switch’s operation and your overall system.

Testing and Verifying Proper Transfer Switch Operation

To guarantee your transfer switch operates correctly, regular testing and verification are essential. Begin with visual and mechanical inspections, checking for heat damage, corrosion, loose components, and dirt. Clean contaminants with a dry cloth or brush—avoid compressed air. Perform internal inspections only when power is off, examining wiring and components for damage or overheating. Conduct insulation resistance tests on control wiring, ensuring resistance exceeds 2 megohms and wiring matches system ratings. Execute functional tests by simulating power loss to verify automatic transfer to emergency power, re-transfer after restoration, and system interlocks. Confirm voltage- and frequency-sensing relays operate correctly. Proper testing procedures help ensure compliance with regulatory guidelines and system reliability. Regularly inspect, calibrate, and record test results to ensure your transfer switch remains reliable and ready to respond when needed.

Maintaining and Inspecting Your Transfer Switch for Longevity

Regular inspections are key to extending your transfer switch’s life. You should perform weekly visual checks and annual mechanical and electrical tests to catch issues early. Proper cleaning, using gentle methods and manufacturer-approved products, helps maintain peak performance over time. Routine checks help identify early signs of wear or contamination, which can prevent costly repairs and downtime. Additionally, staying aware of automation in business can inform maintenance schedules and improve operational efficiency.

Regular Inspection Routines

Performing consistent inspections of your transfer switch is essential for ensuring its reliable operation and extending its lifespan. Regular checks help you catch issues early before they escalate. Here are three key routines to follow:

- Visual and Physical Inspection: Check the exterior monthly for damage, moisture, or contamination. Annually, inspect interior components for wear, discoloration, or damage, ensuring all parts are secure and clean. Exterior signs of damage or corrosion can indicate underlying issues that may compromise system safety. Regular visual inspections also help identify potential issues caused by environmental factors such as humidity or pests, which can affect overall performance.

- Mechanical and Electrical Contact Checks: Examine contacts for erosion, pitting, or heat damage. Confirm that the transfer mechanisms and wiring are intact, tight, and free of corrosion or damage. Proper contact maintenance is crucial for preventing failures during power transfers and ensuring safety.

- Functional Testing: Perform monthly load testing under operational conditions. Verify timing, sensing, and transfer functions to confirm the switch operates within manufacturer specifications and safety standards. Understanding the detailed specifications of your transfer switch can help optimize its performance and longevity. Consistent inspections keep your transfer switch dependable and safe.

Proper Cleaning Procedures

Consistent cleaning and inspection of your transfer switch help maintain its reliability and extend its service life. Always de-energize the switch before cleaning to prevent electrical hazards and damage. Use soft-bristled brushes or dry microfiber cloths to remove dust and grime; avoid abrasive materials. Vacuum instead of compressed air to prevent debris from lodging inside and static buildup. During cleaning, check for moisture or corrosion, and use safe solvents like isopropyl alcohol to remove grime. Inspect contacts, terminals, and insulation for signs of damage or wear, replacing parts as needed. Tighten connections to manufacturer specifications. After cleaning, perform functional tests, verify indicator responses, and ensure the enclosure is secure. Document all activities and update NFPA-compliant testing labels for safety and compliance. Regularly referencing manufacturer guidelines and NFPA standards ensures your maintenance procedures meet safety and quality benchmarks. Additionally, inspecting for moisture and corrosion can prevent future electrical failures and extend your switch’s lifespan.

Frequently Asked Questions

Can Transfer Switches Be Installed Outdoors?

You can’t install a transfer switch outdoors because most are rated only for indoor use, which safeguards them from environmental damage. Instead, mount the switch indoors near your main electrical panel for safety and compliance, and run weatherproof conduit to outdoor-rated power inlet boxes. This setup ensures safe generator connection while keeping the transfer switch protected from weather, reducing risks and maintaining system integrity.

How Often Should I Inspect My Transfer Switch?

Like a well-oiled machine, your transfer switch needs regular care. You should inspect it weekly for visual and mechanical issues, ensuring wiring and components stay tight and undamaged. Monthly, perform operational tests by transferring loads to verify proper function. Quarterly, have a qualified technician conduct a thorough review. Don’t forget annual maintenance, including cleaning and replacing worn parts. Consistent inspections keep your system reliable and compliant, preventing unexpected failures during critical moments.

What Are Common Wiring Mistakes to Avoid?

To avoid wiring mistakes, guarantee all connections are tight and secure, using manufacturer-approved terminals and proper insulation. Avoid loose or exposed wires, and double-check grounding and control wiring setups, especially when multiple switches are involved. Don’t overlook proper wire sizing to prevent overheating, and regularly inspect for damage or corrosion. Follow electrical codes strictly, and always use the correct tools and techniques to ensure safe, reliable operation.

Is a Permit Required for Transfer Switch Installation?

You need a permit for installing a transfer switch, especially for permanent or whole-house setups. Even if it’s a small, portable generator, check with local authorities to verify permit requirements. This step guarantees your installation meets safety standards, code compliance, and utility regulations. Securing the permit and passing inspections protect you from legal issues, insurance claims, and safety hazards, making your backup power system both reliable and compliant.

Can I Install a Transfer Switch Myself?

You can install a transfer switch yourself if you have the proper electrical knowledge and skills, but it’s risky. You need to understand wiring, circuit ratings, and safety procedures. Local codes may require a licensed electrician, especially for outdoor or complex setups. If you’re confident in your abilities and follow all safety guidelines, you can do it, but when in doubt, hiring a professional guarantees safety and code compliance.

Conclusion

By following these best practices, you guarantee your transfer switch operates safely and reliably. For example, imagine a homeowner who installed theirs near the main panel, avoiding common hazards and code violations. Regular testing and maintenance kept the system in top shape, preventing costly outages during a storm. Stick to these guidelines, stay vigilant, and your transfer switch will serve you well, providing peace of mind when you need it most.